Share this

5th Time's the Charm: FAQs from your Swagelok Customer Service Reps

by Taryn Hardes on Thu, Oct 16, 2014 @ 13:10 PM

This edition's FAQs have been answered by your Edmonton and Drayton Valve associates.

1. What is the difference between PFA, PTFE, and Teflon? |

|

Diane Rode:

Teflon® is a fluoropolymer. PFA (perfluoroalkoxy) and PTFE (polytetrafluoroethylene) are both forms of Teflon.

PFA was conceived by DuPont Co. and is melt processable. It is most commonly used for lab equipment as it has an extreme resistance to chemicals. PFA flexible tubing is good for highly corrosive process applications.

PTFE is most known for being the non-stick coating for pans and cookware. It is also used in applications for corrosive and reactive chemicals as PTFE is non-reactive. Compared to PFA, PTFE has a higher flex life (capacity to endure repetitive folding) and is slightly more heat resistant. PTFE is also less affected by weathering and water absorption but has a lower salt spray resistance.

Swagelok offers a variety of fittings and tubing in PFA as well as ultrahigh purity PFA fittings. You can use Teflon or metal fittings with Swagelok PFA tubing. Please remember that PFA tubing must be grooved for use with PFA tube fittings.

Most Swagelok hoses are PTFE lined for flex advantage and handling reactive and corrosive chemicals. Swagelok SWAK is also PTFE-based, which helps lubricate threads and prevent costly thread damage due to galling and seizing during assembly.

2. What is a weld socket fitting and why would I need it? |

Don Keith:

A socket weld fitting is a type of weld fitting that incorporates a tube or pipe socket machined into the fitting which provides tube/pipe support ahead of the weld area. Swagelok pipe socket weld fittings feature socket depths that equal or exceed ASME B16.11 requirements.

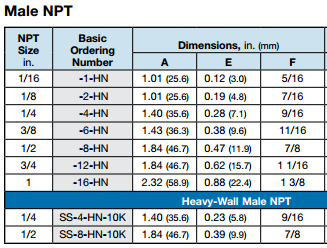

3. What size wrench do I need for Swagelok pipe fittings? |

|

Jon Cool:

The size of wrench depends on the size of the fitting. Please refer to the ‘F’ (i.e. flat) dimension in the Swagelok Pipe Fittings catalogue MS-01-147 for proper wrench sizes.

|

|

4. What is the correct orientation of Swagelok ferrules? |

|

Shelley Lott:

Swagelok tube fittings come from the factory with nuts and ferrules already assembled in the correct orientation but we also offer replacement nuts and ferrules, so how do you know if you are putting them together correctly?

|

|

|

The front ferrule (the beveled or cone shaped piece) sits inside the matching bevel on the Swagelok Fitting to form the sealing surface. The back ferrule (the smaller ring shaped piece) is the tricky one. It is responsible for gripping the tubing, so it’s important to get it right. The back ferrule does have a beveled side to it, and that sits inside the front ferrule. The flat side of the back ferrule sits against the inner shoulder of the nut.

If you are worried about ferrule orientation, or have lots of fittings to rebuild, we do have a handy solution for you. Our “Nut and Ferrule Sets” offer 5 complete sets of Nuts and Ferrules on an arbor to keep them properly oriented from the factory to your fitting. Ask your local distributor about these today!

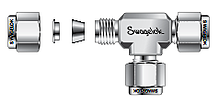

5. How do I find my own authorized Swagelok Sales and Service Centre? |

|

Shelley Lott:

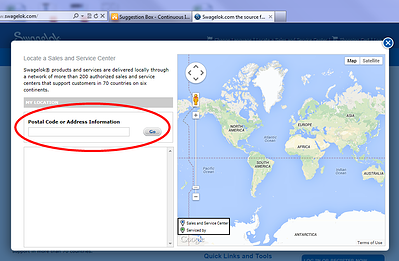

Swagelok is pleased to offer a network of more than 200 authorized sales and service centers that support customers in 70 countries on 6 continents. Wow! But how do you know who to contact?

Go to our website [www.swagelok.com] and click the link in the upper tool bar that says “Locate a Sales and Service Center”.

|

|

Enter your Postal Code or Address information in the box provided to return the authorized distributor information for your area.

Register as a user on our site to have access to online quoting and ordering features with your local authorized distributor. We look forward to hearing from you!

Have any questions? Ask us!

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (2)

- About Us (1)

- April 2024 (2)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)