Share this

Swagelok Tube Fitting Advantage Still Strong After 67 Years (2024 Updates)

by Jim Begg on Tue, Nov 04, 2014 @ 10:11 AM

Updated design means better performance required by today's advanced technology

When the Swagelok tube fitting was introduced in 1947, it provided a vast improvement over the other options for connecting tubing to pipe in the day: pipe threading, flare tubing connections, or the original compression tube fittings developed in the 1800’s. But that was 67 years ago. How does the design stack up in the 21st century?

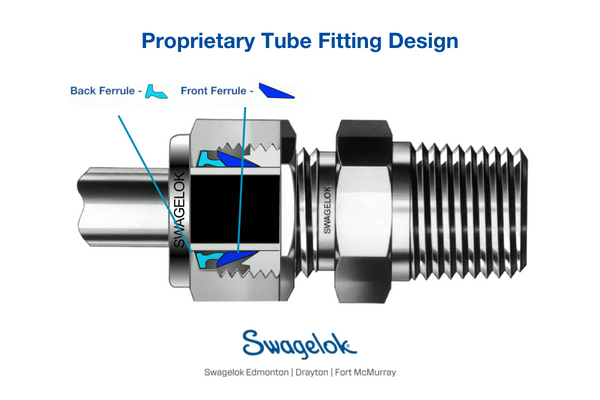

A cross-section of Swagelok's two-ferrule fitting. We invite you to visit the new 2024 Fittings Page at this website. You'll find more illustrations, local answers to common fittings questions, tips videos, and essential literature for download.

Over the years fluid system design has evolved from one of high volume at low pressure to today’s need for low volume at high pressure. These new demands call for increased internal and external pressures, vacuum levels, flow velocities, vibration levels, shock, and impulses. As a result, the mechanical demands on tube fittings, tubing runs, and other system-related equipment have increased accordingly.

Swagelok remains ahead of the curve to make sure its two-ferrule fitting keeps living up to its global reputation for consistency, quality, and performance. I feel very fortunate to have worked for an organization that has made such significant design improvements to its flagship product that it qualified for three design patents for the products over the last 60-plus years. Anyone that knows anything about patents knows that you don’t qualify for a new 17-year patent unless you’ve made some significant design changes.Most people likely don’t know that we have a current patent for our Swagelok Tube Fitting that has been more than 60 years in development. Swagelok’s corporate culture encourages continuous improvement. Everything can always be done better.

Two beats one

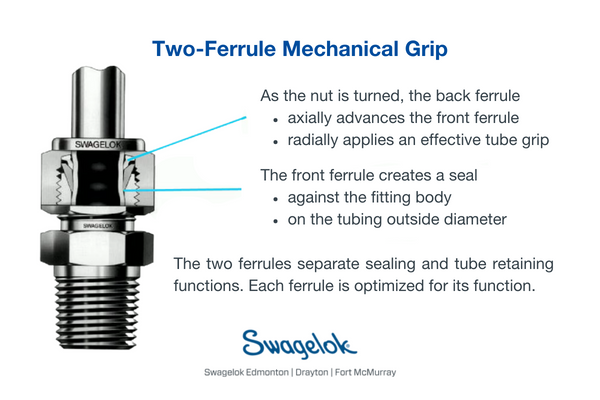

So why are two ferrules important in the swaging process? The design provides better tube-gripping action, reduced potential for improper pull-up, improved sealing in gas service, and vastly improved resistance to vibration.

In a two-ferrule tube fitting design, the back ferrule moves the front ferrule forward to spring-load the fitting assembly, burnish and seal with the fitting body, and create the primary tubing seal. The back ferrule also swages the tube to provide the grip needed to keep the fitting and tubing firmly in place.

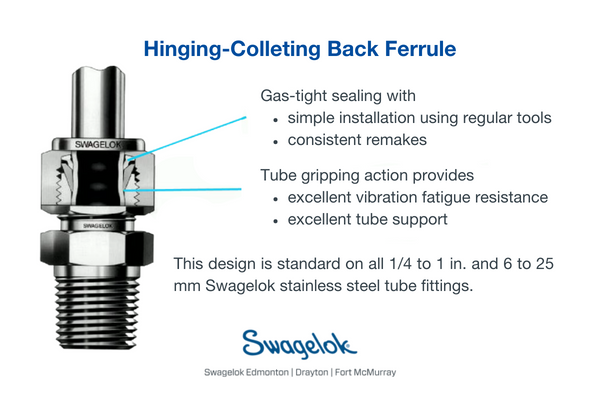

To swage and grip the tube properly, Swagelok’s patented Sat 12 hardening process provides a recessed and contoured geometry of the back ferrule. This process creates a hinging and colleting action that grips the tube and provides more of the back ferrule to be in close contact with the tube to enhance vibration resistance. None of our competitors use this patented, state-of-the-art process.

Swagelok's two-ferrule system compensates for wide variations in tubing variables, including wall thickness, hardness of the tube, and material. Swagelok also provides a longer sealing path than other designs because of the way the back ferrule lifts up the front ferrule to its sealing position. This sealing position is not in just one point but along the complete surface of the fitting body. The back and front ferrules interact and seal according to the wall thickness, hardness of the tube, and the tolerances on the outside diameter of the tubing.

Because Swagelok created the design and remains the industry leader, some people refer to any two-ferrule fitting as a Swagelok fitting, the same way that some people refer to any brand of facial tissue as Kleenex.

Proper installation

Swagelok demands exacting tolerances in the manufacturing of our components. With Swagelok, you always know that the gap between the nut and the body will be predictable. Swagelok is the only manufacturer to actively promote the use of a Gap Inspection Gauge to make sure a fitting has been tightened the proper amount.

Improper make-up and tightening remain the leading cause for tube fitting leakage. One of the biggest reasons why tube fittings fail is that installers sometimes rely on torque rather than the recommended 1 ¼ turn installation practice. But in our training classes, we demonstrate why it's not wise to go by feel, especially when different combinations of materials feel different during tightening.

Our reputation

At Swagelok Edmonton we put our reputation on the line by offering the Swagelok Limited Lifetime Warranty, which states that, "Swagelok hereby warrants to the purchaser of this product that the non-electrical components of the Product shall be free from defects in material and workmanship for the life of the Product. The purchaser’s remedies shall be limited to replacement and installation of any parts that fail through a defect in material or workmanship."

No one else offers a lifetime warranty and will pay for the labour to install the products if they’ve been deemed defective. Swagelok paved the way all those years ago with its original two-ferrule design, and continues to set the industry standard.

Dive deeper with the Swagelok Tube Fitter's Manual

If you would like more information on the Swagelok tube fitting, you are welcome to download the Swagelok Tube Fitter's Manual here →

Finding answers to fluid system questions

We offer experts trained to help customers resolve fluid system challenges. Onsite and remote support available.Talk with us about analytical instrumentation, gas distribution, grab sampling, or any other fluid system issue. We listen to understand your priorities, gather information on your systems and routines, and offer detailed recommendations. Our goal is to help identify opportunities to increase reliability while lowering costs and risks.

At our Contact page you'll find several options for getting in touch. Please click through and choose one that's convenient for you.

Related articles

- Don't Throw Out Those Swagelok Fittings Upon Disassembly

- Choosing Swagelok Tubing & Fitting Alloys? Engineered Combinations Resist Corrosion & Minimize Cost

- New Swagelok Training: FK Fitting Essentials

- Advantages of Swagelok VCO Fittings and VCR Face Seal Fittings

- FAQ: How Fast Can You Deliver a Fully Built Custom Fluid System Assembly?

- Small Bore Tubing Has Big Advantages Over Traditional Piping

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (2)

- About Us (1)

- April 2024 (2)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)