Share this

Swagelok's Calibration & Switching Module Adds Efficiency to Sample Conditioning

by Katie Dennis on Wed, Aug 19, 2015 @ 09:08 AM

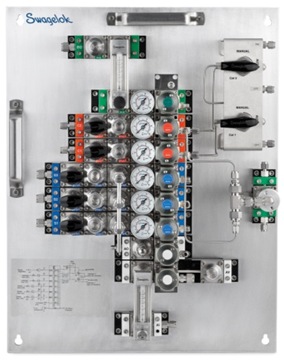

Swagelok's Pre-Engineered Subsystem (PrESS) handles multiple lines in a small footprint

The Calibration and Switching Module (CSM) is one of five Swagelok Pre-Engineered Subsystems. To read more about the key features and benefits of this module, download the CSM catalogue.

All process samples must be conditioned to meet an analyzer’s requirements. Conditioning includes verifying that a sample is being inserted into the analyzer at the appropriate pressure, temperature, flow, and filtration level. Swagelok's Calibration and Switching Module (CSM) not only conditions the sample, but allows you to easily switch among multiple sample lines and introduce calibration gas to the system.

It's installed right before the analyzer.

Mix and match

Each calibration and switching module is made to your order. It can be as simple as a ball valve and a stream selector, or you can add a host of inlet assemblies: gauge, filter, relief valve, and pressure regulator. Determine how many sample lines you will be working with, and how many calibration lines. Then tell us what kind of flow control you need at the outlet. We can even include manual calibration.

The design eliminates the problem of having lots of dead volume filled with an old sample. These so-called "dead legs" can lead to contamination of the next sample. That's especially true if the different lines contain different substances, say methanol, gasoline and propane. The Swagelok design pushes out all of the old sample.

MPC means easy configuration

We build this pre-engineered subsystem on Swagelok's modular platform component system. That means not only quick assembly, but ease of maintenance for you, and a small footprint. We've built an eight-line system with a footprint of roughly 2 feet by 3 feet, able to fit into a small enclosure with a heater.

The foundation for the MPC system is the substrate channel. A variety of drop-in components provide the main flow path from one surface-mount component to the next. Locator pins on the components fit into corresponding holes in the channel. Putting them together is, literally, a snap. Channels come in a variety of lengths that can handle up to 14 surface mount positions.

On top of the substrate layer comes the manifold layer. The same system of locator pins allows you to create the flow path between up to six parallel substrates.

Next come the various Swagelok surface-mount components that make up the fluid distribution system. Standard O-rings provide leak-tight seals between each surface-mount and substrate flow component and between the substrate and manifold flow components.

If you have a rail that's not long enough, you remove a cap and add an extra piece. Or if you realize you don't need a particular piece such as a filter, simply remove the component and cap it off. Pieces also can be put in a different order. All it takes is a simple Allen key.

Complete details about the Calibration and Switching Module are just a click away at Swagelok's CSM application guide.

Additional resources

- Swagelok Parts: Modular Platform Component Systems Set the Standard

- Todd Scorah: Our Man Serving at the Oil Sands

- Swagelok's Fluid Distribution Headers: Easy, Fast, and Versatile

In a hurry or have a question? Please click here to get in touch - we respond fast! Or call 780.437.0640

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (2)

- About Us (1)

- April 2024 (2)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)