Share this

Use a Swagelok Regulator to Speed up Analytical Systems

by Katie Reid on Fri, Nov 18, 2016 @ 12:11 PM

In an ideal world, you would be able to get a fluid sample instantly from the process line to the analyzer. The real world, alas, it is far from ideal. So it's important to learn a bit about time delays and how do minimize them.

First, realize that a delay may occur in any of the major parts of an analytical instrumentation system: the process line, the tap and probe, the field station, the transport line, the sample conditioning system, the stream switching system, and the analyzer itself. A small delay at each stage will add up.

One way to minimize the delay is with a pressure regulator. In gas systems with a controlled flow rate, the lower the pressure, the faster the gas moves, which means the shorter the time delay.

The lower the pressure of a gas, the shorter the time delay to the analyzer

Start at the tap

Ideally you want to tap the process line as close to the analyzer as possible. But you also want to stay upstream of drums, tanks, dead legs, stagnant lines, or other sources of delay. Because of that, you may have to make do with a location that's less than ideal. If the tap is a long distance from the analyzer, a fast loop is a good means of quickly delivering fluid to the analyzer and returning the unused portion to the process.

Another typical source of time delay is the probe. The larger the probe's volume, the greater the delay. Minimize the delay by choosing a low-volume probe.

At the field station

For an analyzer that requires a liquid sample it is better not to use a regulator. High pressure will help prevent the formation of bubbles. But with a gas sample, a field station is one of the means of reducing pressure in the transport lines. Time delay decreases in direct proportion to absolute pressure. At half the pressure, you will get half the time delay. The sooner the pressure is dropped, the better, so put the field station as close to the tap as possible.

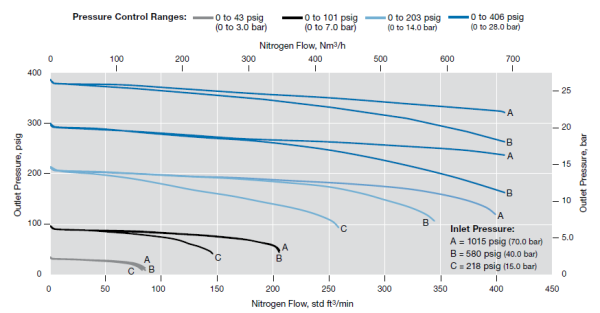

There are a few different ways to configure the regulator. With a drop in pressure, almost all gasses lose heat. If the gas is close to its dew point, the result from this cooling is condensation. In some cases, the loss of heat may be great enough to cause the regulator to freeze up. In those cases, a heated regulator may solve the problem. If you don't expect condensation, a standard regulator will probably do. Read more about Pressure Regulators and how to read a flow curve here.

If a liquid must become a gas before it can be analyzed by a gas chromatograph or other analyzer, it's time for a vapourizing regulator.

Another means of attaining a faster response is to move the regulator closer to the analyzer with the aid of a second fast loop.

The details

There's a lot more to these tips than simply plugging in a component. Vapourizing regulators, in particular, require extra care because the volume of a sample can increase greatly as it changes from liquid to gas. Done incorrectly, the addition of a vapourizing regulator can actually increase the time delay to the analyzer.

We love to discuss regulators, analyzer systems and all things dealing with fluid systems. Tell us about your analyzer system and let's get started finding the right configuration.

Related articles

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (2)

- About Us (1)

- April 2024 (2)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)