Share this

Capping Off Tubing vs Plugging Off Ports - Photos, Video, PDFs

by Katie Reid on Tue, Jan 31, 2023 @ 08:01 AM

Tube fittings should seal and enable consistently tight-fitting installations. How do you choose between a cap and plug? We have tips, a video, and a free PDF that may help.

First, let's get oriented. Caps and plugs are types of tube fittings. Male connectors, crosses, adapters, reducers, unions, elbows, and tees are other types of tube fittings. Swagelok fittings are 1/16 to 2 in. in size with NPT, ISO/BSP, and SAE threads; constructed of 316 stainless steel, carbon steel, brass, 6-moly, or one of several alloys.

Installed properly, both caps and plugs can be pressurized so that you can fully pressure test a system to specifications.

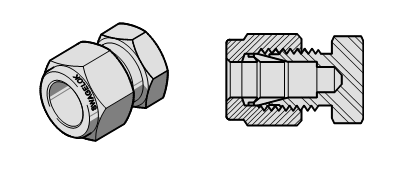

Tube Cap

Use caps to cap off tubing.

A cap is a complete Swagelok assembly including nuts, front ferrule, back ferrule, and a fitting body. The fitting body is blank rather than open. This allows you to install the nuts and ferrules onto the tubing and pre-swage them onto the tubing. As with a regular tube fitting, it takes only one and 1/4 turns to pull it up into place. After installation, you can pressurize your system.

The video below in this post covers both assembly and reassembly. Additional information is on page 64 of the Tube Fittings catalogue (free download).

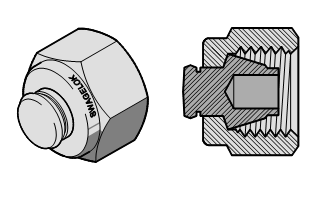

Tube plug

Use plugs to close off ports.

A plug is used to close off a port. If you have a tee, for instance, and want to use only two of the three ends, use a plug. You remove the nuts, ferrules, and tubing; take the plug and tighten it on the end you want to close off. The plug already has machined ferrules inside, so you don't need to pull it up 1 and 1/4 turns after it's finger-tight; you tighten it only 1/4 turn, and the job is done. As with the cap, a plug allows you to fully pressurize your system.

The following video covers the difference between fitting caps and plugs and the most effective way to assemble each:

Click to play this demonstration video.

If you are planning an assembly and testing of a fluid system or subsystem, consider exploring what we offer. The Custom Solutions team at Swagelok Edmonton builds analytical subsystems, gas distribution systems, grab sampling systems, hose assemblies, regulator assemblies, and much more.

Consultation, fabrication, and pressure testing are included. Your assembly arrives ready to install, and is covered by the same warranty as our individual parts. We can advise on installation and maintenance too.

Our testing capabilities add significant value for customers. We can leak test with hydro, pneumatic, and helium leak test equipment. We offer tighter testing tolerances than traditional leak tests — testing down to 1x10-6. No project is too large or too small, and even if the project has a short turnaround time, we may be able to assist.

We have posted a collection of free resources about fittings, as well. With the Tube Fitting Installation & Inspection Resource Collection, in one step you get our Installer's Pocket Guide for Swagelok Tube Fittings, how-to videos, the Fitting Installation & Troubleshooting Technical Briefing Video that goes more in-depth, and other information.

We have also posted at this blog about closely related topics, like how to choose fittings, ferrules, and tubing materials for your applications (in some cases materials should not match); how to apply PTFE tape to tapered pipe threads; and the advantages of adapter fittings.

Swagelok offers over 6,000 standard parts, and Swagelok Edmonton maintains over 10 million in local inventory. We have all the caps and plugs you need, along with a full range of other fluid system components. Please get in touch if we can answer any questions. Just click below and share a little information, or call 780-437-0640.

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (2)

- About Us (1)

- April 2024 (2)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)

.png)