Share this

Compare Our Tube-in-Tube Coils to Pre-Packaged Sample Coolers

by Tristian McCallion on Thu, Apr 29, 2021 @ 09:04 AM

Did you know Edmonton Valve builds tube-in-tube coils (examples below) in sizes up to one inch tubing, in a wide variety of materials? And that our team is standing by help with all the flow, temp, and other necessary calculations?

Examples of tube-in-tube systems we can locally fabricate. For details please get our new Comparing Tube-in-Tube Systems Resource Collection:

The offering grew out of noticing a pattern in customer needs. Many customers have coils that were provided as part of an initial instrumentation package on their boilers. And most facilities have multiple generators.

It's common for them to have a preventative maintenance program that calls for replacing coils, say, every couple of years. So customers asked us, "is there another option besides these pre-packaged coolers?'" And the answer is "yes".

Swagelok coils complement pre-packaged options

In SAGD environments with steam generator constraints, in particular, customers benefit from having a range of cooler options.

When we talk with you about the design, we'll ask about your flow rate, your sample pressure, your sample temperature, your cooling media, and more. Once we know these details we can start to look at the options be it a tube-in-tube coil fabricated here in Edmonton or be it a Sentry prepackaged cooler.

The overall goal is to make sure that as that sample gets to either the analyzer or to the sample bottle that it's safe for the equipment and for personnel. Yet our customers operate in some of the harshest conditions on earth.

Built tough for challenging fluid, higher flows, longer service

Our systems tend to be able to handle challenging fluid, have higher flow, and cost less than pre-packaged options. Also our systems tend to be available in a broader range of materials, and we can fabricate locally. Through our Field Advisory Services we can help with your temperature calculations and the flow calculations, as well to ensure what's delivered is exactly what you need for your application. And it's also a bit easier to replace when necessary.

We are highly responsive, and we are local. Often we can turn these tube-in-tube systems a little quicker and at a lower price than you'll get with pre-packaged systems.

Safe sampling operations

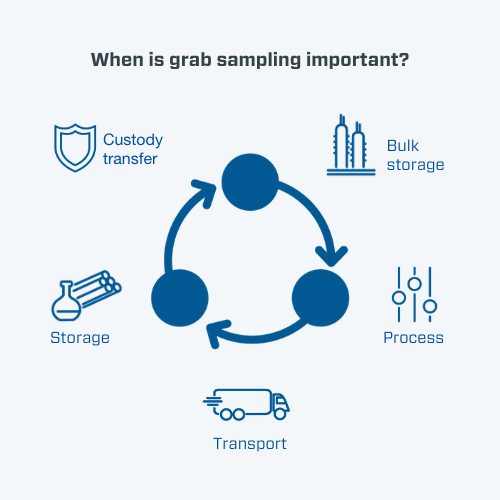

Grab sampling is essential for validating process conditions, showing the end products meet quality specifications, ensuring online analyzers are fit for use, and tracking product quality through custody transfers. It can also provide verification of environmental emissions.

Grab sampling is essential for validating process conditions, showing the end products meet quality specifications, ensuring online analyzers are fit for use, and tracking product quality through custody transfers. It can also provide verification of environmental emissions.

In all of these cases, capturing a representative sample is essential. But many processes operate at high temperatures, which means risk of operators being scalded and risk of exceeding the temperature limits of seats and seals. Swagelok recommends consideration of a sample cooler at supply temperatures above 140°F (60°C).

We see high supply temperatures in a range of oil & gas, power, chemical refining, and semiconductor applications. And in SAGD environments, the challenge is compounded by steam generator constraints.

Our Field Advisory Services team can help you determine the size and heat transfer for your coil design and make other key choices. Then we can build, test, and deliver your cooler ready to install and commission.

Exotic materials, special flow configurations, and more

The standard configuration of our tube-in-tube systems is a helical coil. But many other configurations are available. Indeed, we can meet a wide range of needs with respect to design, radius, tube sizes, end connections, materials of construction, and pressure ratings. We offer 316L stainless steel, carbon steel, special alloy tubing such as inconel and monel, and other exotic materials.

All components used in the construction of our tube-in-tube systems have Canadian Registration Numbers (CRN's), as well as a letter of compliance, materials test reports (MTR's), and other documentation. Each assembly is built in accordance with the Alberta Boilers Safety Association (ABSA) Certificate of Authorization Permit. And Swagelok products are backed by The Swagelok Limited Lifetime Warranty.

Get the new Edmonton Valve Resource Collection: Comparing Tube-in-Tube Systems

Our new Edmonton Valve Comparing Tube-in-Tube Systems Resource Collection includes our new Swagelok Tube-in-Tube Systems brochure (PDF), Industrial Steam Sampling Best Practices Technical Briefing (video), Stainless Steel Seamless Tubing and Tube Support Systems catalog (PDF), and more.

We are also happy to answer any questions you might have, and help you specify a system. Need technical help right now? Call our 24x7 Field Advisory Services On-Call Technical Support: 780-237-7109.

About Tristian McCallion, Custom Solutions Manager, Edmonton Valve

Edmonton Valve has relied on McCallion for 26 years. His current title is Custom Solutions Manager. Earlier, he supervised our sales team. Before that, he managed sales throughout Edmonton and northeastern Alberta. For 12 years he also worked with Swagelok Energy Advisors across North America, training customers on steam fundamentals (TAP), testing steam traps, and conducting steam system audits.

Edmonton Valve has relied on McCallion for 26 years. His current title is Custom Solutions Manager. Earlier, he supervised our sales team. Before that, he managed sales throughout Edmonton and northeastern Alberta. For 12 years he also worked with Swagelok Energy Advisors across North America, training customers on steam fundamentals (TAP), testing steam traps, and conducting steam system audits.

Also see:

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (2)

- About Us (1)

- April 2024 (2)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)