Share this

How To Reduce Fugitive Emissions with Valves for Better Compliance in Alberta

by Thomas Webster on Tue, Jan 04, 2022 @ 13:01 PM

Regulatory requirements and increasing focus on environmental, health, and safety concerns have made fugitive emissions reduction one of the hottest topics in Alberta oil and gas operations. Fugitive emissions come from countless sources, but valves are the most common. In a typical industrial facility, approximately 60 percent of fugitive emissions come from valves.

Valves present the greatest point of leakage in any system. Preventing fugitive emissions with low-emission valves is a high priority, and not just because of regulations—emissions hurt profitability by leaking valuable products, not to mention the risks to health and safety. Fortunately, these risks can be mitigated by developing a fugitive emissions management plan that includes high-quality valves designed for low emissions.

Risks of Fugitive Emissions from Valves

Fugitive emissions can have major consequences for the health and safety of the environment, your people, and your business. Some of the risks and effects include:

- Contribution to climate change

- Environmental pollution

- Health problems resulting from long-term exposure to harmful gases

- Fire and explosion hazards

- Market-based incentive under Greenhouse Gas Pollution Pricing Act: facilities that are less efficient have to pay, while those that are more efficient gain credits that can be held or sold

- Repair is not enough: detected potential leak points are subject to fines

- Financial losses resulting from lost product and downtime

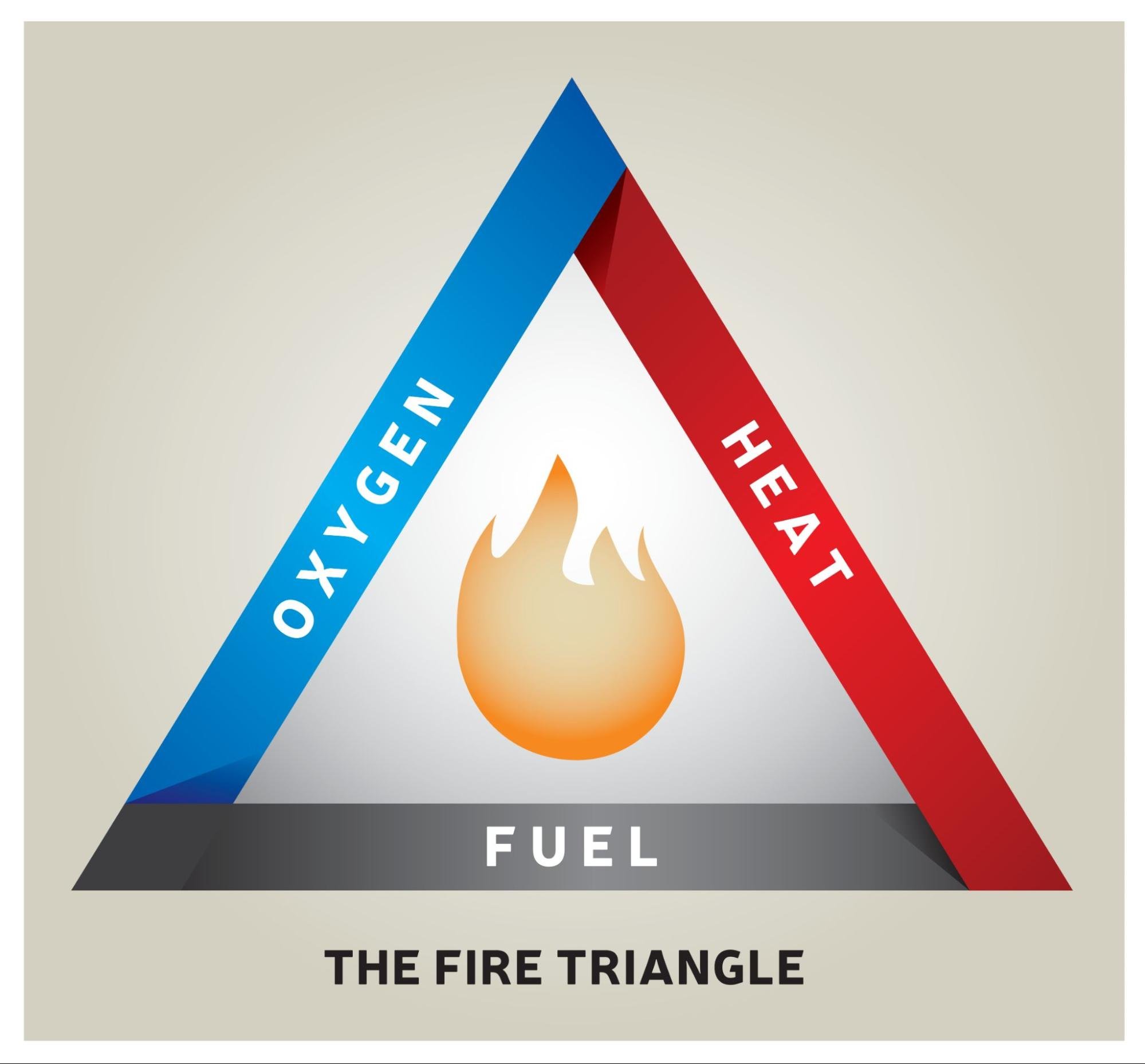

The Fire Triangle

The “fire triangle” (pictured right) shows the three elements needed to ignite a fire: oxygen, fuel, and heat. Oil and gas facilities can mitigate the risk of fires by removing or limiting one or more of those elements; for example, by keeping all fuel sources free of oxygen. However, fugitive emissions release flammable gas into the atmosphere, mixing with oxygen and forming two legs of the fire triangle. If concentrations of emitted gases are high enough, a small spark can ignite a fire or cause an explosion.

The “fire triangle” (pictured right) shows the three elements needed to ignite a fire: oxygen, fuel, and heat. Oil and gas facilities can mitigate the risk of fires by removing or limiting one or more of those elements; for example, by keeping all fuel sources free of oxygen. However, fugitive emissions release flammable gas into the atmosphere, mixing with oxygen and forming two legs of the fire triangle. If concentrations of emitted gases are high enough, a small spark can ignite a fire or cause an explosion.

The Cost of Lost Product

Oil and gas producers in Canada lose over 30 billion cubic feet of methane gas to fugitive sources every year. This means billions of dollars of valuable product is lost forever. In addition, regulatory penalties can make the financial impact even harder if fugitive emissions don’t comply with regulations. End users face increased economic costs in these scenarios—inefficiency that hurts any operation’s bottom line.

Fortunately, there are many cost-effective ways to mitigate fugitive emissions from valves.

Reducing Fugitive Emissions from Valves

Because valves are such a high risk for fugitive emissions, it’s important to use only high-quality valves and prioritize their maintenance and repair. Reliable, low-emission valves can make a huge difference in reducing fugitive emissions across a facility.

Replace Aging Valves

Fugitive emissions often come from older valves that have either worn out, suffered damage, or were designed with older materials or technologies. By thoroughly inspecting and testing valves throughout the facility for leaks, you can identify the main “problem components” and strategically upgrade the ones with the greatest impact.

When upgrading aging valves, make sure to select only the highest quality products, and be sure they are optimized for your specific processes.

Valves from Swagelok to Prevent Fugitive Emissions

Multiple low-emission valves are available depending on your operation’s needs:

- Instrument Ball Valve: For any gauges or instrumentation needs, the 40 Series (including the 40G and 40T/40E lines) are available with API 641 Certification. These valves have been tested to emit below the stringent 100 ppmv standard and are available from 1/16- to 3/4-inch sizing.

- Process Ball Valve: This valve is available for piping systems. The 60 Series also are available with API 641 certification and are available in 1/8 to 2-inch sizing.

- Instrument Needle Valve: A needle valve can be used for flow-metering applications. Several styles are available with API 624 low emission certification.

- Double Block and Bleed Valve: This valve combines block and bleed valves for interface with other components, isolates upstream and downstream flow, and is employed in component maintenance/repair/replacement. Depending on the valve type, API 624 and 641 Certification are available.

- 5-Valve Manifolds: These may be used on differential setups and provide the ability to block, equalize, and vent two process conditions.

With so many factors affecting valve performance, it’s important to consult with a valve expert to help you decide what materials and options your process requires.

Follow a Valve Preventive Maintenance Program

Even new, high-quality valves can leak if they aren’t correctly installed and maintained. A preventive maintenance program is an essential part of any fugitive emissions plan to detect small leaks before they become big ones. A valve and fluid system expert can perform an onsite consultation to identify high-risk components and help set up an effective preventive maintenance program.

Get Expert Help Reducing Fugitive Emissions from Valves

Fugitive emissions from valves pose risks to health, the environment, and your bottom line. Edmonton Valve & Fitting understands the importance of reducing fugitive emissions and is here to help you select valves to make your facility safer and more efficient. To ensure you’re getting the best possible components for your system, one of our Field Advisors can perform an onsite evaluation and provide recommendations for emissions-reducing valves.

Swagelok valves, without design modification or special ordering instructions, passed the API Low-E test for fugitive emissions. By using Swagelok valves, you meet and exceed the strictest standards in the industry and keep your people, equipment, and products safe. Plus, using Swagelok valves means your components are protected by Swagelok’s industry-leading Limited Lifetime Warranty.

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (2)

- About Us (1)

- April 2024 (2)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)