Share this

Does Your Gas Distribution System Release More Fugitive Emissions Than Alberta Allows?

by Thomas Webster on Mon, Jul 04, 2022 @ 08:07 AM

Gas distribution systems are a key component in Alberta refineries. However, problems with a gas distribution system may result in excess fugitive emissions. This creates additional costs due to inefficiencies and may run afoul of Alberta emission regulations—regulations that are continually being updated based on changing environmental and societal needs.

This article will discuss issues within gas distribution systems that contribute to fugitive emissions, methods to reduce emissions, and how working with a trusted Alberta gas distribution system provider can equip your refinery with the components and support to reduce fugitive emissions.

The Role System Components Play in Fugitive Emissions

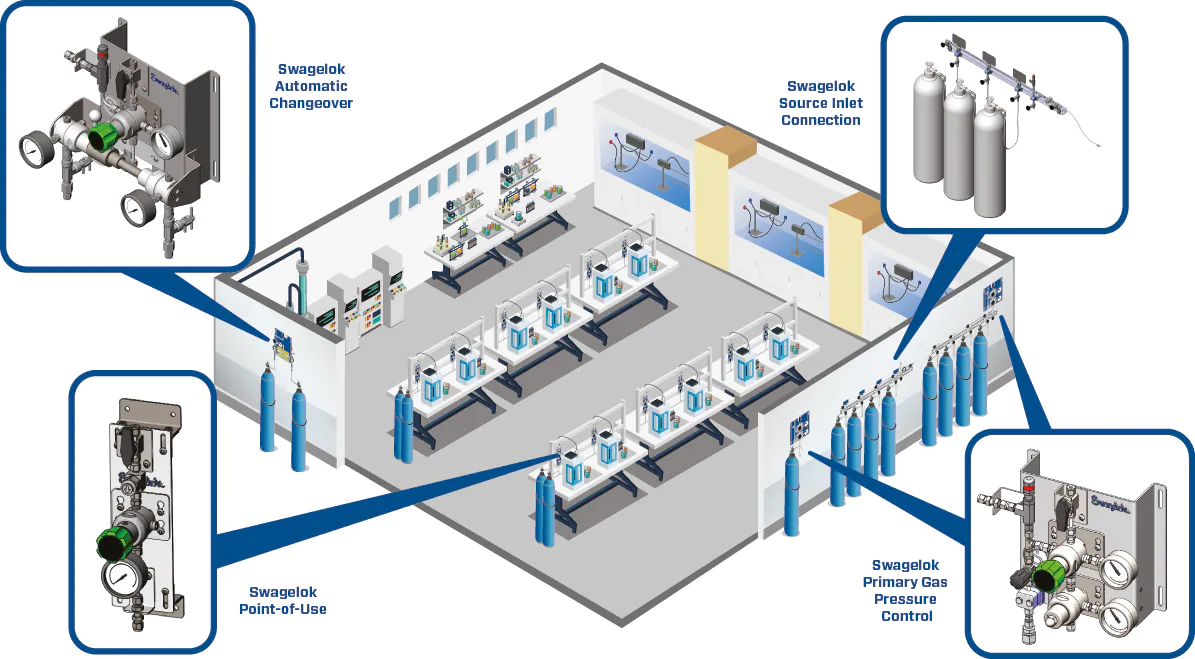

Gas distribution systems are comprised of several components that are responsible for controlling the flow and pressure of gas. Each of these components is a potential source of fugitive emissions. The four major components (source inlet, primary gas pressure control, automatic changeover, and point-of-use) of a gas distribution system and the associated risks are discussed below:

Source Inlet

The gas source is connected to the gas distribution system by the source inlet. There are several components of the source inlet, including cylinder connections, hoses, tubing, filters, vent, purge, and relief functions. The pressure from the gas source is often significant, and, as such, the components of the inlet must meet pressure standards. Components that fail to meet pressure standards will result in increased wear and tear and, ultimately, additional leaks releasing costly gases to the atmosphere.

Primary Gas Pressure Control

The primary gas pressure control utilizes pressure regulators to reduce gas pressure to a safe and effective level for operations. Issues sometimes occur when needing to adjust delivery pressures based on the changing internal and external environment. This is particularly true in situations with changing temperatures. Incorrect control of pressure can cause damage to the system and leaks to occur.

Automatic Changeover

An automatic changeover is needed to continuously supply the gas. The automatic changeover utilizes two pressure regulators that allow the gas source to be changed from the service cylinder to the reserve one, without shutting down operations. Poor design and implementation of the automatic changeover—as well as wear and tear—may result in fugitive emissions being released when changing between gas sources. Standardization within these panels can help mitigate fugitive emissions that occur as a result of poor design.

Point-of-Use

The point of use provides operators the ability to measure gas pressure and adjust gas based on needs. The point-of-use system involves a pressure regulator, gauge, and isolation valve. Leaks may occur if these components malfunction and pressure is either measured incorrectly or is not properly controlled.

Luckily, there are solutions to mitigate the causes of fugitive emissions.

Fugitive Emission Mitigation Strategies for Gas Distribution Systems

Fugitive emissions are a concern for many industries in the region in terms of cost, operating issues, and environmental damage. There are several strategies that can help mitigate the amount of fugitive emissions.

- Update tubing and valves: Updating tubing and valves in a gas delivery system will reduce emissions by limiting leaks and seal issues. Tubing and valves should meet pressure and temperature regulations of use. Further, the chemicals in the system should be checked to make sure they are not corrosive to the materials constructing the tubing and valves.

- Update and maintain gas distribution systems: The components of a gas delivery system should be continually checked and monitored to make sure they are not worn out. Small damage can increase fugitive emissions and result in excess strain on other components of the system, which compound gas delivery system issues.

- Utilize reliable materials for system components: When implementing, updating, and repairing the gas delivery system, it is important to be aware of the gasses used in the system and the pressure and temperature of operation. Some gasses may need to have components that are constructed of materials that can withstand high pressure and corrosion from the gasses involved.

- Leverage leak detection and monitoring: Detecting and monitoring leaks and then quickly repairing components is one of the best methods to limit fugitive emissions. Being able to quickly get replacement components and materials—such as tubing, valves, and seals—will allow for repairs to be made with minimal fugitive emissions.

- Conduct on-site audits: Regularly planned auditing of the gas distribution system will allow for potential problems to be identified before they become big problems. On-site audits from a trusted provider will provide insight into components that need to be replaced and potential sources of fugitive emissions.

- These methods for reducing fugitive emissions from gas delivery systems are beneficial in terms of limiting inefficiencies and costs, limiting a cascade of component failure, and adhering to Alberta fugitive emission standards. To effectively implement these methods, it is imperative to partner with a provider that can utilize their expertise to quickly assist you with your gas delivery system needs.

Partner with Edmonton Valve & Fitting to Reduce Fugitive Emissions

A local gas distribution system provider will be familiar with Alberta’s emissions standards and can advise you on how to reduce fugitive emissions. Whether you’re working towards compliance with fugitive emissions standards or you want to exceed the minimum requirements for improved performance, you can trust Edmonton Valve & Fitting to provide advice and components to maximize your facility’s efficiency and reliability. Our expert Field Advisors can perform an onsite evaluation and give recommendations to help reduce fugitive emissions from your gas delivery system and other sources in your facility.

To find out more about how Edmonton Valve & Fitting can help you reduce fugitive emissions and improve efficiency with high-quality gas delivery systems and components, contact us through our website or by calling 780-437-0640.

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (3)

- About Us (1)

- April 2024 (3)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)