Share this

Selecting a Gas Distribution Management System

by Thomas Webster on Fri, Jul 15, 2022 @ 08:07 AM

.png)

Selecting, installing, and the management of an appropriate gas distribution system is critical for the petrochemical industry in Alberta. Petrochem facilities require a gas distribution management system that is designed to fit specific needs based on the chemicals used, the required pressure, and flow of gasses, and the space limitations of the existing layout. Successfully and efficiently getting gasses from the source to the end process is not only about limiting waste and lowering costs but also about making sure end processes can be successfully completed.

Choosing a gas distribution management system involves understanding the subsystems within that gas distribution management system and how those components work with processing needs. Typically, those subsystems are:

- source inlet connection

- primary gas pressure control

- automatic changeover

- point-of-use

We will describe below the importance of the subsystems within a gas distribution management system, their relationship to the processes in use, and the benefits of working with a local Alberta vendor for your gas system needs.

The Role of Subsystems Within a Gas Distribution Management System

A gas distribution management system must adhere to Alberta processing requirements and regulations. To ensure this, each of the four subsystems within the gas distribution system must work in conjunction to fit processing requirements. Let’s take a look at each subsystem and the requirements for efficient operation.

Source Inlet Connection

The source inlet connection subsystem connects one or more high-pressure fluid supplies to the gas distribution system. This subsystem includes cylinder connections, tubing, hoses, and filters. It may also include vent, purge, and relief functions to ensure gas from the cylinder(s) is safely delivered to the primary gas pressure control or automatic changeover subsystems.

To prevent failure, it is imperative that the tubing of the source inlet works with the requisite pressure standards and be constructed of a material that does not react with the gas being used. The tubing also needs to create a strong seal between components of the gas distribution system and the valves and cylinders being used.

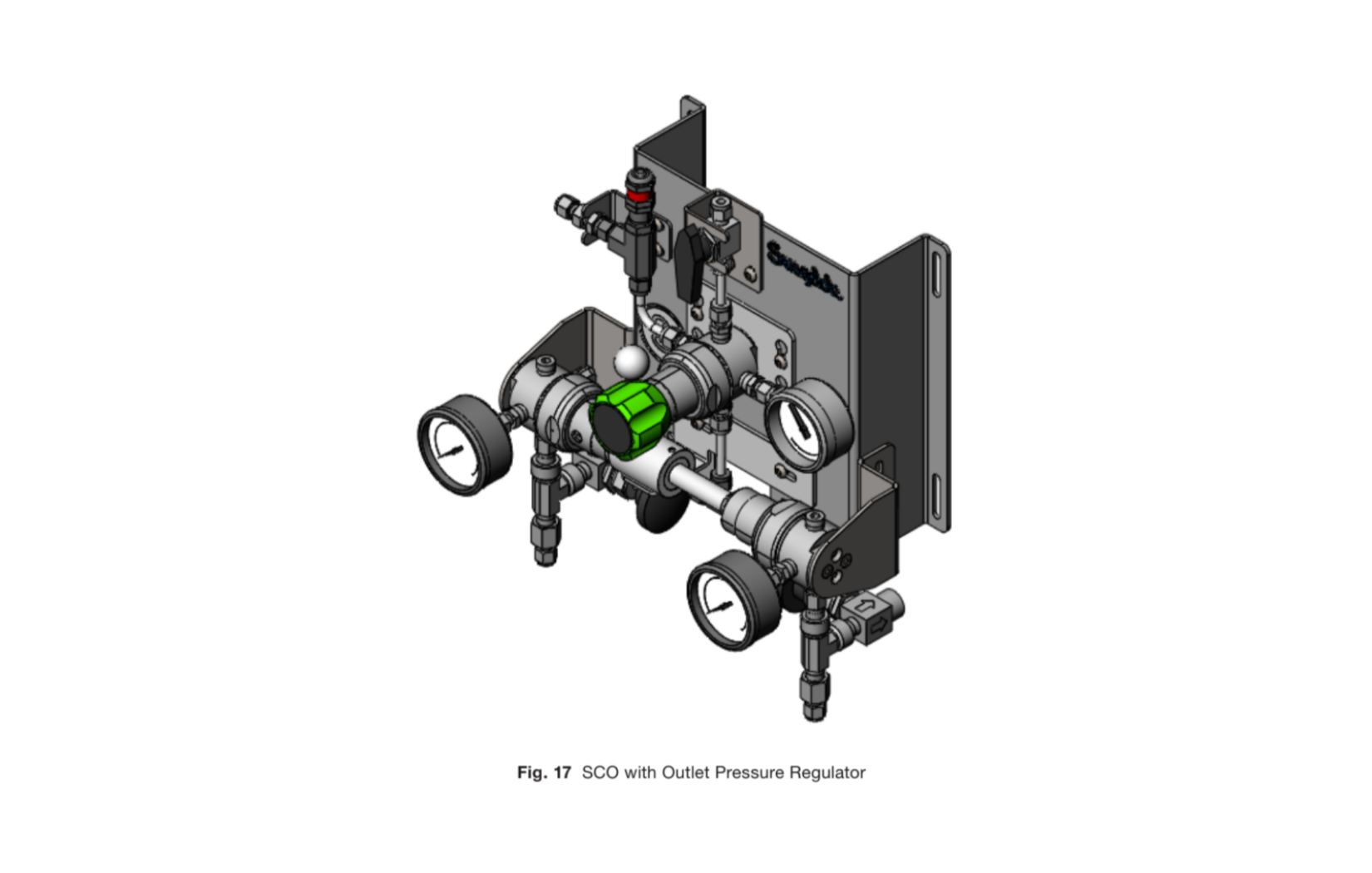

Primary Gas Pressure Control

The primary gas pressure control panel allows operators to monitor gas as it flows through the gas distribution system. Primary gas pressure control panels are extremely important to alert personnel to potential problems in the gas distribution system. Changes to the pressure may indicate a leak or that a contaminant has entered the system. These issues may pose safety hazards to operators and risks of toxins being released into the environment. Gas pressure control panels also utilize pressure regulators to alter the flow and pressure of the gas to fit optimal standards.

Automatic Changeover

The automatic changeover manifold allows for seamless switching between gas sources without the need to stop the flow of gas. It is important to consider the overall infrastructure when selecting an automatic changeover manifold as there are several design options.

Auto changeover manifolds can be autonomous or semi-autonomous.

- The semi-autonomous manifold utilizes pressure differential for the initial switch, but then requires an operator to switch back.

- The autonomic changeover manifold senses the pressure differential and then automatically switches back and forth.

The needs of the gas distribution system should be considered when selecting between the different types of changeover manifolds. There are high purity manifolds (which incorporate two diffusion-resistant regulators to allow for the changeover system to be completely isolated); high-flow primary changeover systems (which provide an uninterrupted high flow of gas); electronic changeover systems (which utilize electric sensors to provide a fully automatic changeover when one of the gas cylinders become depleted); and liquid changeover systems (which are used for administering vapourized gas from cryogenic containers).

Point-of-Use

The point-of-use is the last stage of pressure control prior to gas usage. This subsystem utilizes a pressure regulator, gauge, and isolation valve to adjust pressure. When deciding on a point-of-use subsystem, it is important that the gauges and isolation valves are compatible with the requisite pressure, temperature, and chemicals in the system. And, these units are closest to the end user, they need to be intuitive and safe.

Additional Considerations

Cylinders, valves, and tubing are important to consider to keep gas distribution management systems operating at peak efficiency while minimizing maintenance issues and costs.

- Having high-quality cylinders with the appropriate pressure specifications will help prevent gas leaks. It is also recommended that cylinders use a bypass line to purge chemicals and quick connects to allow for safe disconnecting from the system.

- The tubing for a gas distribution management system should be composed of materials that do not react or corrode with gasses in the systems. The size and fit of the tubing should also correspond with the ideal pressure and flow of the gas in the system.

- Valves should be selected based on needs for continuous, semicontinuous, or discrete gas flow. Valves should be constructed of materials that are not corroded or damaged when in contact with the gasses in the system.

Selecting and implementing these components for a gas distribution management system can be tricky. If even one component does not meet processing standards—for aspects such as pressure, temperature, flow rate, and chemicals used in processing—it will result in costly inefficiencies with extra processing gas needing to be purchased, excess fugitive emissions, and additional wear and tear throughout the system. Working with a local Alberta vendor of gas distribution management systems can provide you with the expertise and understanding to get the most out of your gas distribution management system

Partner with Edmonton Valve & Fitting for Your Gas Distribution Management System Needs

Edmonton Valve & Fitting can help Alberta industries with the selection, implementation, and maintenance of a gas distribution management system. Regardless of your processing needs, our team of experts can assist you in making decisions about the subsystems and components necessary for the safe and efficient operation of your gas distribution management system.

Our Field Advisors can evaluate and optimize your existing gas distribution system and recommend quality Swagelok components that can improve safety and efficiency. Or, we can provide design support for a custom gas distribution system from the ground up to optimize your gas handling applications. Our gas distribution system design and fabrication services include standardized, modular systems and industry-leading Swagelok components customized to your specific needs.

To find out more about how Edmonton Valve & Fitting can assist with the design and assembly of gas distribution management systems in your facility, contact us through our website or by calling 780-437-0640.

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (3)

- About Us (1)

- April 2024 (3)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)