Share this

Ensure Grab Sampling Accuracy: Advantages and Disadvantages of Common Features in SAGD Operations

by Thomas Webster on Fri, Dec 17, 2021 @ 07:12 AM

Grab sampling is a diagnostic tool used to snapshot a system process or environmental product. Being able to analyze a process at any point in the greater system lends insight into how the system is developing and allows for the diagnosis of issues where process design went awry. In SAGD, the biggest challenges revolve around the temperature and viscosity of the fluid. The temporal nature of these snapshots can be deceiving, however: samples can rapidly volatize, meaning long-term storage or extended transit for study could have misleading findings, at best. Even with this drawback, some diagnostic information is better than none. Despite notable constraints on measurement and analysis, grab sampling advantages and disadvantages merit discussion for industry best practices.

Grab sampling is a collection of a product in-process, and it is of high importance that the sample be representative of the mixture it is being collected from. Two factors play an outsized role in determining whether the sample is representative: the collection, and the volatility and susceptibility of the sample to outside conditions once removed from the mixture.

Grab Sampling Advantages and Disadvantages at a Glance

While grab sampling is a valuable diagnostic tool for obtaining an informative peek into system processes, there are many considerations that should be heeded to ensure the proper course of action (if any) is taken following sample analysis. Any changes to a system based on the false assumptions of a non-representative sample or a sample that has changed drastically from the initial mixture could potentially lead to further issues when calibration and adjustments are applied. The goal for grab sampling must therefore be a sample that is representative and at the very least has any differences that arise due to a change in environment accounted for.

To better evaluate options, here’s a closer look at grab sampling advantages and disadvantages:

| Pros | Cons |

| Invaluable diagnostic tool | Results possibly misleading if not properly accounted for |

| Allows systematic review of individual processes of larger SAGD operations | Review can only be as good as sampling; certain samples may be more susceptible to the environment once removed from the original mixture |

| Gas and liquid mixtures can be analyzed | Pressurized mixtures must be held in cylinders (non-pressurized liquids can be collected in glass or polyethylene bottles) |

| Sampling technology allows for continuous motion, for instance in the case of liquids that would otherwise freeze without continuous flow | Sampling of mixtures in excess of 60°C should be cooled to prevent injury to operators; samples at lower temperatures will tend to solidify; cooling sample may reduce the representativeness |

Properly collected and analyzed, grab sampling allows operators to peer directly into their system processes and fine-tune to the specific needs of their environment. Care should be taken in sample collection, both for sample integrity and operator safety when handling certain samples (extreme temperatures, high pressure, corrosive, etc.).

Choosing the Right Panel for Sampling

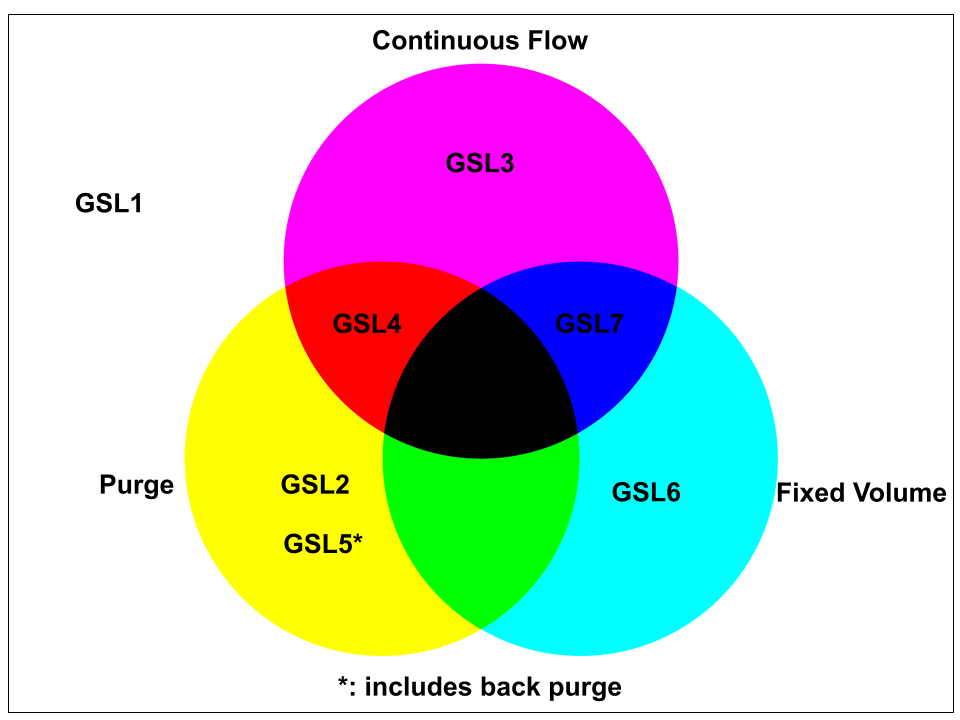

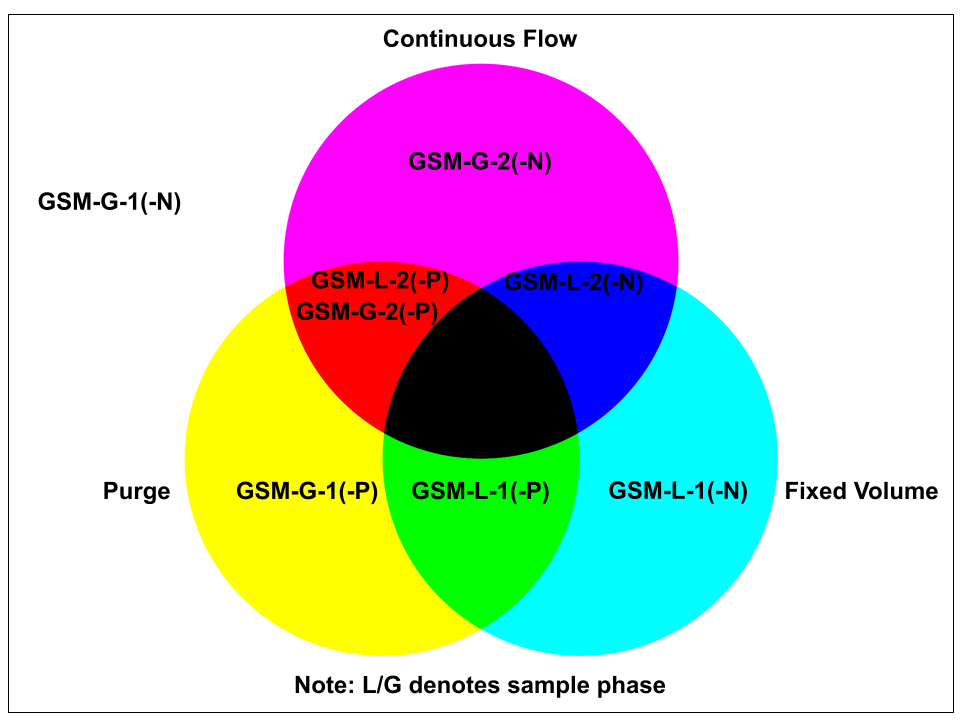

Due to the wide range of samples available for collection in SAGD industries, there exist numerous panels designed and calibrated for particular needs. One big distinguishing factor is the style of grab sampling systems, separated on the basis of pressurized and non-pressurized samples: grab sample modules (GSM) and liquid-only sampling systems (GSL). GSM panels can be designed for either pressurized gas or liquid retention, while GSL covers all other liquids. In addition to pressurization, there may be additional concerns for sample collection, such as continuous flow to prevent freezing, purging for toxic or corrosive elements, and fixed-volume containers to prevent overfilling. Pictured below are two infographics to help choose the correct grab sampling panel as determined by sample needs.

The manner of sample collection may come into play beyond the container itself. GSM panels contain a closed-loop system that allows for the sample to flow into the collection and out to a lower pressure location in the system. For some samples, this can eliminate the need for purging of the grab sampling system entirely. Meanwhile, GSL panels will have slightly different applications depending on gas or liquid sampling: gases should fill the container top-down to push out any liquid or condensate and liquids bottom-up to push out any vapour.

Weighing Options for Grab Sampling Advantages and Disadvantages

The ability to evaluate SAGD processes step-by-step allows for an unmatched level of diagnostic feedback; Field Advisors can support your system at any stage from assessment to assembly. Edmonton Valve & Fitting can customize panels that are specifically designed for the unique requirements of SAGD, especially for temperature and viscosity. We are committed to the long-term operation of your grab sampling system with training for your employees on proper usage and maintenance.

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (2)

- About Us (1)

- April 2024 (2)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)