Share this

Use Our Mechanical Efficiency Program to Keep Your Plant in Top Shape

by Katie Reid on Tue, Mar 05, 2019 @ 11:03 AM

We'll cover rotating equipment, energy surveys, and small-bore tubing

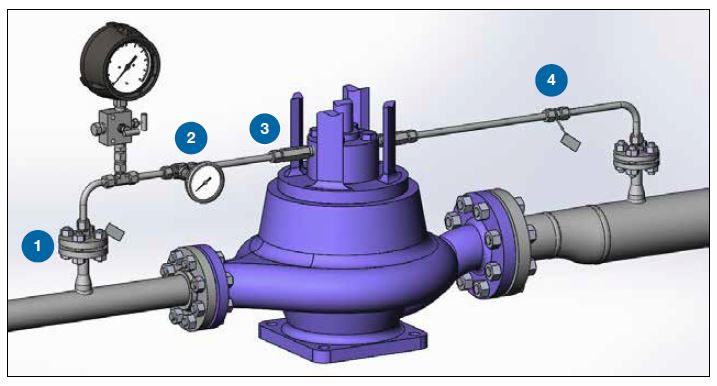

Let us help you improve the way you connect in your plant's operations with Edmonton Valve's offering of custom configurations of Swagelok's Seal Flush components. Request a copy of our Mechanical Seal Support Systems PDF to learn about the various plans and design principles.

Eventually every plant develops some problem areas. Maybe it's a "bad actor" pump the keep having problems, or leaky pipes. That's the time to call Edmonton Valve and tap into our Mechanical Efficiency Program (MEP).

Our MEP program covers three basic areas: The first is rotating equipment, such as seal support systems for pumps and compressors. The second is energy management. The third is conversion from traditional piping to small-bore tubing of 2 inches and smaller. Think of it as a unified set of services for the non-instrumentation side of your operation.

Hat trick

A plant may need only one of the three services at a given time. That's fine with us. But as we check out one area, our discoveries can lead to another.

Let's say a plant needs us to check out its seal support systems on rotating equipment. We have a number of pre-engineered seal support plans that we can fabricate. We also have specialized fittings that make working on those systems easier, reducing the number of connection and leak points and making the connections more reliable. They usually save some space too.

While we're checking out the rotating equipment, we may find areas where the piping is leaking on the fuel lines. And that, in turn, could turn into a discussion of replacing hard pipe with small-bore tubing. For several years now, the API 682 4th Edition standards for rotating seals have suggested using tubing over traditional piping systems. Pipe threads are notorious for leaking, and a lot of plants are trying to replace them to improve reliability on the seal support systems.

Local fabrication

Edmonton Valve also offers the advantage of local fabrication. We can build panels for rotating equipment right here, which means it's easy to produce custom work.

All it takes to get started is to call Edmonton Valve & Fitting at 780-437-0640, or drop us a note using the Message Us on our website.

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (3)

- About Us (1)

- April 2024 (3)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)