Share this

Insulated Tubing Gives You Temperature Control

by Katie Reid on Fri, Oct 28, 2016 @ 12:10 PM

Because it differs from ordinary tubing, so do the installation instructions

There are times when ordinary tubing alone won't get the job done. One of those times is when you need to control the temperature of the fluid inside, or control the surface temperature of the tubing itself. That's when you might want to consider insulated tubing - download the catalogue below.

Swagelok insulated tubing is designed for use in applications such as steam supply, condensate return, and gas and liquid transport lines, where weatherproofing and energy conservation are important. It helps protect personnel from hot process and steam lines, reduces heat loss, and offers a cost-effective alternative to field-installed insulation of small-diameter tubing systems.

Tubing lengths and bends

Because the tubing itself is different, so is the installation procedure.

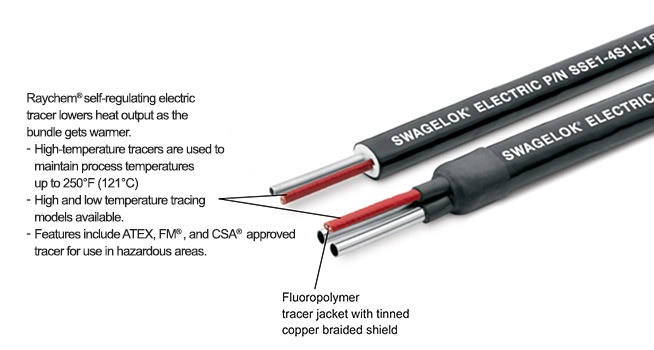

First consider the length of tubing. You'll want to allow at least 12 inches of straight tubing before connecting it to fittings. For steam-trace tubing bundles, add enough length to connect the tracer to the supply connection and to the return connection. For electric-traced tubing bundles, add enough length to connect to the power supply. Include 6 inches for inside the junction box. Don't forget to include extra length to heat any other devices at the end of the bundle. Also, use the approved power connection and termination kits.

You'll want to use a centerline tool when you are bending tubing bundles to connect them to instrumentation. Start by cutting and removing the jacket and insulation on the tubing, so that you can see the process and tracer tubes. Insert the tube bundle through the seal boot in the tool, unscrew the center nut, and remove the center bend shoe. Now you'll be able to fully insert the tube bundle and gently bend the tubes against the outer shoes.

Install the center bend shoe and tighten the center nut. Bend the tubes against the center shoe until the tubes are parallel. Insert the tube bundle through the seal boot again, and remove the tubing bundle from the tool. To protect the insulation, seal the bundle ends with a heat shrink end seal boot.

Need further assistance on installation or have questions on our pre-insulated tubing bundles? Call our office, we are here to help at (780)-437-0640

Also see

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (2)

- About Us (1)

- April 2024 (2)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)