Share this

Choosing Among Mechanical Seal Support Flush Plans for Optimal SAGD Processes

by Tristian McCallion on Thu, Aug 05, 2021 @ 09:08 AM

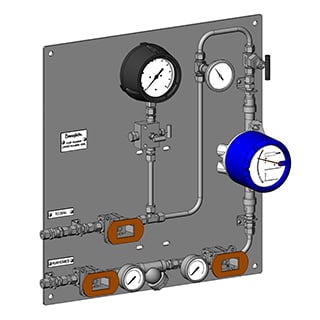

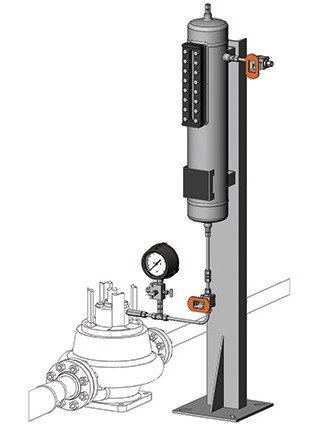

Mechanical seal support flush plans circulate fluid through mechanical seals to maintain adequate lubrication, pressure, temperature, and solids content in the seal chamber. The flush plan creates an optimal environment for the seal, preventing wear and failure and prolonging its life. The reliability of a SAGD operation depends on flush plans to protect mechanical seals from the harsh, heavy process fluids involved in SAGD.

There are many different API 682 mechanical seal support flush plans suited to different SAGD applications. To ensure a mechanical seal performs efficiently and reliably, it is essential to select the right flush plan to support it. Below we will look at some of the most common mechanical seal support flush plans used in SAGD operations and the benefits of consulting with an Edmonton Valve & Fitting Field Advisor when replacing or installing a new seal support system and flush plan.

Seal Flush Plan Basics: Lubrication, Temperature, Pressure, and Flow

A flush plan delivers either process fluid or an external fluid to the seal chamber at the required pressure, temperature, and flow rate to protect the seal from friction, heat, and solids. The American Petroleum Institute (API) has standardized these mechanical seal support flush plans in API Standard 682: Pumps—Shaft Sealing Systems for Centrifugal and Rotary Pumps.

Mechanical seal support flush plans fall into one of three categories, depending on where the flush fluid is delivered: process-side, dual or in-between, and atmospheric-side.

Process-side Flush Plans

Process-side flush plans lubricate and cool a single mechanical seal by circulating fluid to the seal face exposed to the process fluid. Some process-side flush plans use the process fluid as the flush, while some use plant water or another fluid from a reservoir or external source.

Process-side flush plans lubricate and cool a single mechanical seal by circulating fluid to the seal face exposed to the process fluid. Some process-side flush plans use the process fluid as the flush, while some use plant water or another fluid from a reservoir or external source.

The heavy, dirty fluids of SAGD usually need to be treated before flushing the seal face. Filters, strainers, or cyclone separators can remove solids from the process fluid, and heat exchangers can be used to cool it to a suitable temperature.

Dual or In-Between Seal Flush Plans

A dual or in-between seal flush plan delivers a buffer fluid (unpressurized) or barrier fluid (pressurized) to the seal chamber between two mechanical seals. This provides the most control over the seal environment. Dual seal flush plans are common in SAGD because the process fluids are often not suitable for flushing the seal and cannot be allowed to leak into the atmosphere.

A dual or in-between seal flush plan delivers a buffer fluid (unpressurized) or barrier fluid (pressurized) to the seal chamber between two mechanical seals. This provides the most control over the seal environment. Dual seal flush plans are common in SAGD because the process fluids are often not suitable for flushing the seal and cannot be allowed to leak into the atmosphere.

Atmospheric-Side Flush Plans

Atmospheric-side mechanical seal support systems deliver a quench (an unpressurized fluid) to the seal face exposed to the air. The quench prevents the process fluid from leaking into the atmosphere by absorbing or removing any leakage.

Atmospheric-side mechanical seal support systems deliver a quench (an unpressurized fluid) to the seal face exposed to the air. The quench prevents the process fluid from leaking into the atmosphere by absorbing or removing any leakage.

Common API 682 Flush Plans Used in SAGD Operations

The table below describes the basics of some of the most common flush plans used in SAGD.

|

API 682 Flush Plan |

Description |

Flush Location |

Applications |

|

Plan 11 |

Process fluid recirculates from the pump discharge through a flow control orifice to a single mechanical seal. |

Process side |

Adequate for most general applications with non-polymerizing fluids and sufficient pressure. |

|

Plan 12 |

Process fluid recirculates from the pump discharge through a strainer and flow control orifice to a single seal. |

Process side |

Similar to Plan 11, but with a strainer to remove solid particles from contaminated fluids. |

|

Plan 32 |

Clean fluid from an external source is pressurized through a throat bushing and delivered to a single seal. |

Process side |

Used when the process fluid is unsuitable for flushing the seal because it contains solids or contaminants. |

|

Plan 52 |

Clean buffer fluid is delivered from a reservoir to the outboard seal face in a dual seal arrangement. |

Dual seal |

Used when contamination of the process fluid with a barrier fluid is unacceptable. |

|

Plan 53A, 53B, 53C |

Clean, pressurized barrier fluid is delivered to the inboard and outboard seal faces from a reservoir (53A), bladder accumulator (53B), or piston accumulator (53C). |

Dual seal |

Used for dirty, abrasive, or polymerizing process fluids that would damage the seal faces or flush system, or when leakage of the process fluid into the atmosphere is unacceptable. |

|

Plan 54 |

Clean, pressurized barrier fluid is delivered to the inboard and outboard seal faces from an external source. |

Dual seal |

Used when the process fluid is hot or contaminated with solids or when the pumping ring is unable to supply a sufficient flow rate. |

|

Plan 55 |

Clean, unpressurized buffer fluid is delivered to the inboard and outboard seal faces from an external source. |

Dual seal |

Used when the process fluid may solidify when exposed to the atmosphere or when additional heat removal from the inner seal is required. |

|

Plan 62 |

An unpressurized quench is delivered from an external source to the atmospheric side of a single seal. |

Atmospheric side |

Used when a single mechanical seal requires a quench to operate; prevents coking and oxidation by clearing solids. |

How Do I Know Which Plan to Use?

These are just a few examples of the multitude of mechanical seal support flush plans in API 682. Selecting the best flush plan for the process requires careful consideration of the process conditions, fluid properties, and infrastructure available. The wrong flush plan can adversely affect the process temperature, pressure, and flow, reducing efficiency and potentially causing early seal failure.

In general, the simpler the process, the simpler the flush plan. Hazardous, volatile, or highly viscous process fluids require more complex flush plans to protect the seal.

The safest choice is to consult with fluid systems management experts so you know you’re getting the most efficient, reliable flush plan for your process.

Consult the Experts on Mechanical Seal Support Flush Plans

There’s a lot to know about mechanical seal support flush plans, but you don’t need to have expert knowledge to get the most out of your SAGD operation’s seal support systems, especially when you get an onsite evaluation from one of our experienced Field Advisors. Our Field Advisors are experts in API 682 implementation for SAGD operations and will make sure you get the seal support solution you need.

In addition to determining which flush plan is best for your process, our Field Advisors can make specific recommendations regarding system design, instrumentation, and components to boost reliability.

We build our API 682-compliant systems locally, so you get what you need quickly. We test all systems thoroughly to validate safety, reliability, and ease of maintenance. All our products are backed by Swagelok’s Limited Lifetime Warranty—one of the strongest in the industry.

About Tristian McCallion, Custom Solutions Manager, Edmonton Valve

Edmonton Valve has relied on McCallion for 26 years. His current title is Custom Solutions Manager. Earlier, he supervised our sales team. Before that, he managed sales throughout Edmonton and northeastern Alberta. For 12 years he also worked with Swagelok Energy Advisors across North America, training customers on steam fundamentals (TAP), testing steam traps, and conducting steam system audits.

Edmonton Valve has relied on McCallion for 26 years. His current title is Custom Solutions Manager. Earlier, he supervised our sales team. Before that, he managed sales throughout Edmonton and northeastern Alberta. For 12 years he also worked with Swagelok Energy Advisors across North America, training customers on steam fundamentals (TAP), testing steam traps, and conducting steam system audits.

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (3)

- About Us (1)

- April 2024 (3)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)