Share this

Our CNC Tube Bender Delivers Speed & Accuracy

by Katie Reid on Mon, Mar 05, 2018 @ 14:03 PM

Complex bends and large runs are easy thanks to computer controls

Need a 180-degree tube bend? No problem! Our CNC tube bender is fast and precise. Tube bending is one of our custom solutions, which you can learn more about here:

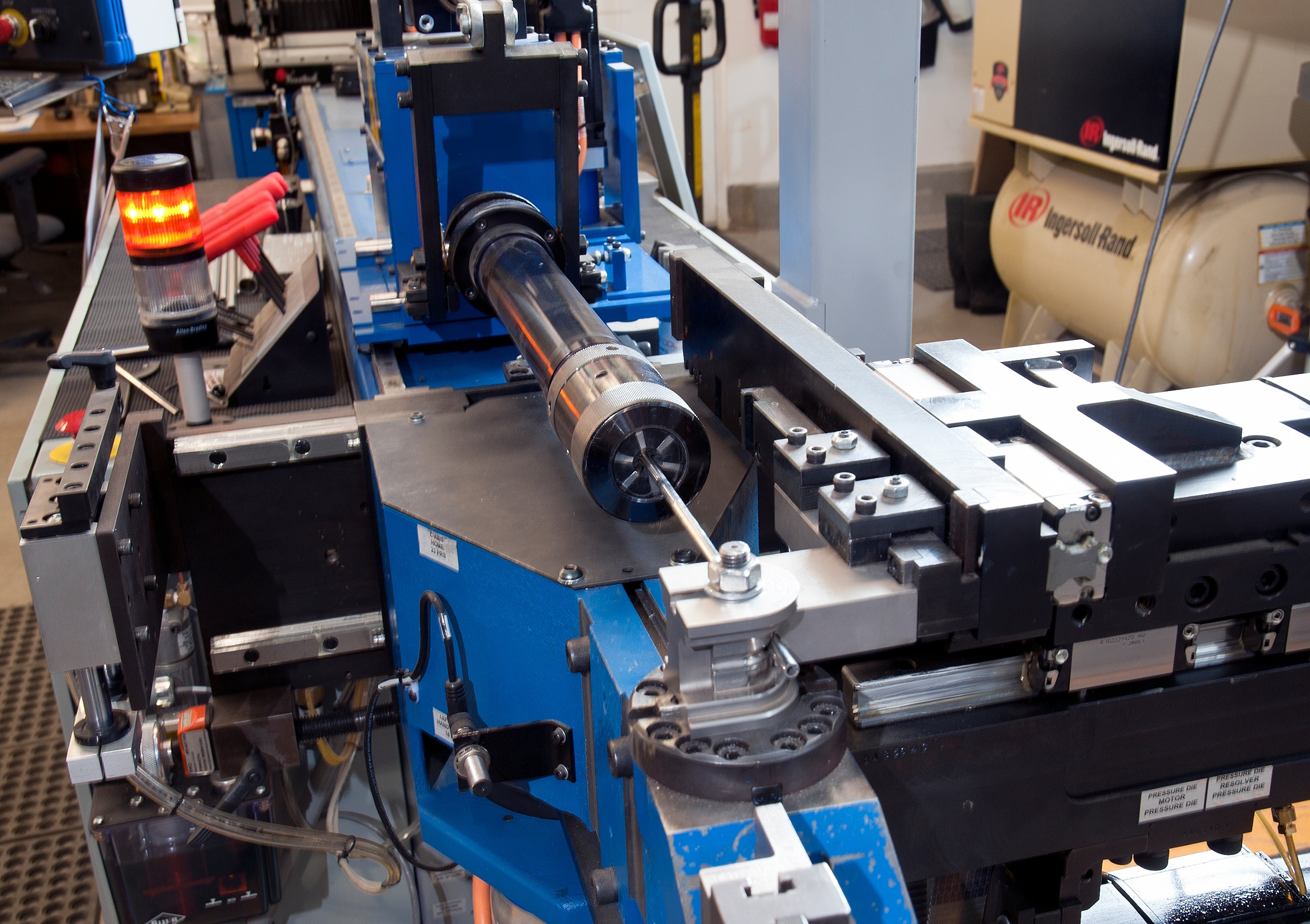

We love to show off our CNC tube bender when customers take a tour of our shop. At 10 feet long, three feet high and three feet wide, this machine looks like a brute. But while it's powerful enough to bend bar stock, we use it instead to bend tubing with delicate precision.

The CNC bender can handle any tubing from a quarter-inch diameter up to one inch, and any wall thickness. It can bend any angle, even 180 degree bends. Its size allows it to handle bends with a radius of up to 42 inches.

One more time

But the big advantage of the CNC bender is repeatability. CNC stands for "Computer Numerical Controls." Once we program your job into the computer, we can create exactly the bends you ask for every time, no matter how complex the combination of angles.

We can create hundreds of finished pieces, and each will be identical. And it's fast, so even if you just need a couple of simple bends in a piece of tubing, the CNC bender is still ideal for the job.

When we finish your job, we store the specifications in the computer forever with a unique identification number. If you gave us a drawing in 2010, you can use it to produce fresh copies today. As with any valuable database, we backup our data to guard against accidents.

Copying and improving

In fact, we don't even have to start with a drawing. Give us the part you want to replicate, and we'll put it in our vector machine that works with the CNC bender. The vector machine scans your part, produces a 3D drawing of it, and sends the information to the bender.

We don't have to worry about wasted tubing, because our machinery will tell us the exact length to cut, down to a thousandth of an inch.

Maybe you have a damaged piece of tubing that you need to replace. We can use that as the starting point to recreate the original. We'll scan it and adjust the drawing to return everything to its proper alignment. We'll even print out the new drawing for you.

Or maybe you aren't exactly sure what the finished part should look like. We can start a drawing and show it to you, then make any adjustments you want until the design meets your approval.

Even if the original part is fine but you want to revise the design, we can adjust the dimensions in the computer to add an inch here or a bend there. The CNC bender assigns a different part number to each version, so you can always go back to the original design if you want.

Quick turnaround

Because the CNC bender is so quick and efficient, we often can turn out a single-part order on the same day it comes in. More involved projects usually can be turned out within a week.

Next: Would you like a demonstration? Please contact us to schedule a time:

(Prefer to talk live? Please give us a call at 780-437-0640.)

For more on this topic, see:

- Tagging Hoses at Edmonton Valve & Fitting (blog article)

- Customers Rate Edmonton Valve's Performance (blog article)

- Forget Trial and Error; Take Our Tube Bending Course (blog article)

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (2)

- About Us (1)

- April 2024 (2)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)