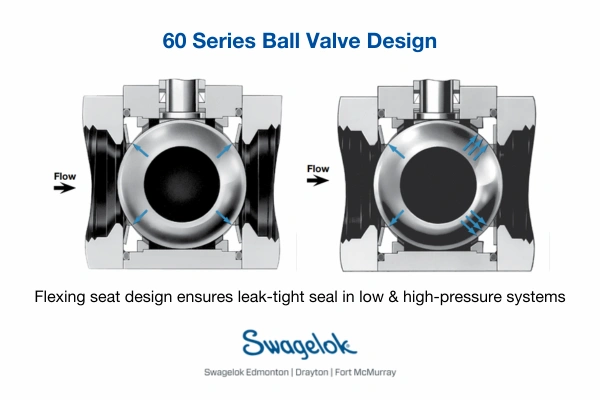

FAQ: Which is the Correct 60 Series Ball Valve?

by Derek Green on Mon, Jan 15, 2024 @ 11:01 AM

Ball valves are a practical and economical way to control flow in a wide variety of applications, and Swagelok's 60 Series offers a highly flexible design in a broad range of sizes. Try our 7-step STA …

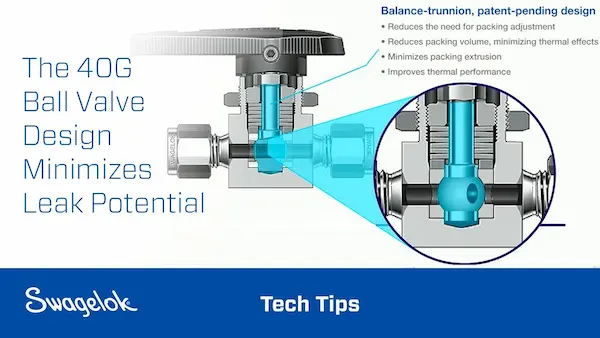

Look Inside: How a 40G Series Instrumentation Ball Valve Minimizes Leak Potential (Video)

by Thomas Webster on Tue, Dec 19, 2023 @ 10:12 AM

Swagelok's 40G Series one-piece instrumentation ball valves maintain fluid integrity, control fugitive emissions, and prevent leaks in general-purpose and critical-service applications. See it in a cr …

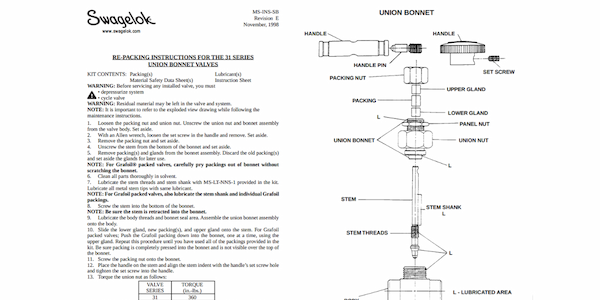

Swagelok's Rebuilding Kits Help You Adjust or Replace Valve Packing (PDF Instructions, Video)

by James Dickie on Wed, Dec 06, 2023 @ 12:12 PM

Learn how to use Swagelok’s rebuilding kits for manually actuated and remotely actuated valves. Each kit contains detailed instructions on how to adjust or replace the packing or rebuild the valve if …

Replacing Industrial Valves? Use This 7-Step Method to Verify Selection

by James Dickie on Thu, Nov 30, 2023 @ 08:11 AM

The average Alberta industrial facility has, on average, 7,400 valves installed. And when a valve wears out, it's typically replaced one for one. But if your system isn't performing perfectly, it's wo …

30 Years Strong: ISA Edmonton & Swagelok Edmonton

by Katie Reid on Tue, Nov 21, 2023 @ 08:11 AM

ISA Edmonton, a local chapter of the International Society of Automation (ISA), has been a fixture in the Edmonton industrial community for 30 years. The organization's primary mission has been to pro …

Beyond Tube vs Pipe: Prefabricated Assemblies with Bent Tubing Offer a Range of Benefits

by Tristian McCallion on Thu, Nov 16, 2023 @ 08:11 AM

You know that using bent tubing instead of traditional piping in some common applications can slash potential leak points and save time during installation. Now save even more with fully built, leak-t …