Share this

SAGD Blowdown: Ensuring Your Sampling Systems Help Optimize Production Costs

by Thomas Webster on Wed, Sep 21, 2022 @ 08:09 AM

With 80% of Alberta’s oil sands buried 150 meters to 450 meters deep on average, steam-assisted gravity drainage (SAGD) is the trusted method for heavy crude oil and bitumen recovery. High-temperature steam is injected into the oil sands through the injection well to lower the viscosity of the bitumen. The heavy oil is then recovered from the production well. In addition to the heavy oil, SAGD also recovers water—90% of which is recycled back into the system.

Often times this recovered water contains dissolved solids, which in high concentration, can damage the system. While most of them are recycled, the organic compounds and solids remain as residue—the “blowdown.” The cost associated with replacing the lost water can be very high, decreasing the overall cost-efficiency of the project. Its impact on the environment can be another hindrance.

A smart way to optimize the cost of production is to use a sampling system that can analyze the quality of the treated water.

SAGD Blowdown and the Need for Sampling

SAGD projects can be costly given their intense energy requirement, and the cost associated with production and refinement. Therefore, water acts as a counteraction because it’s easily available, economic, and can be recycled. When water is converted into steam and fed into the subsurface to extract heavy oil, the water retrieved can be contaminated with many organic compounds and dissolved solids.

As the water is recycled in the boiler, some amount may be discarded to avoid the high concentration of suspended solids. This is because the solids can result in contamination and damage within the boiler. This discarded amount of water is the blowdown which helps to prevent accumulation of the contaminants. However, the major issue with blowdown is that:

- A high blowdown rate is ideal to prevent impurities from concentrating and affecting the recovery process.

- A high blowdown also significantly increases the cost of the project due to the additional cost for:

- Makeup water

- Waste disposal

- Water treatment plant capacity

The makeup water is the amount of water required to replace the water lost during the blowdown. An effective way to minimize the SAGD blowdown rate is through the use of a sampling system.

How Does Sampling System Help?

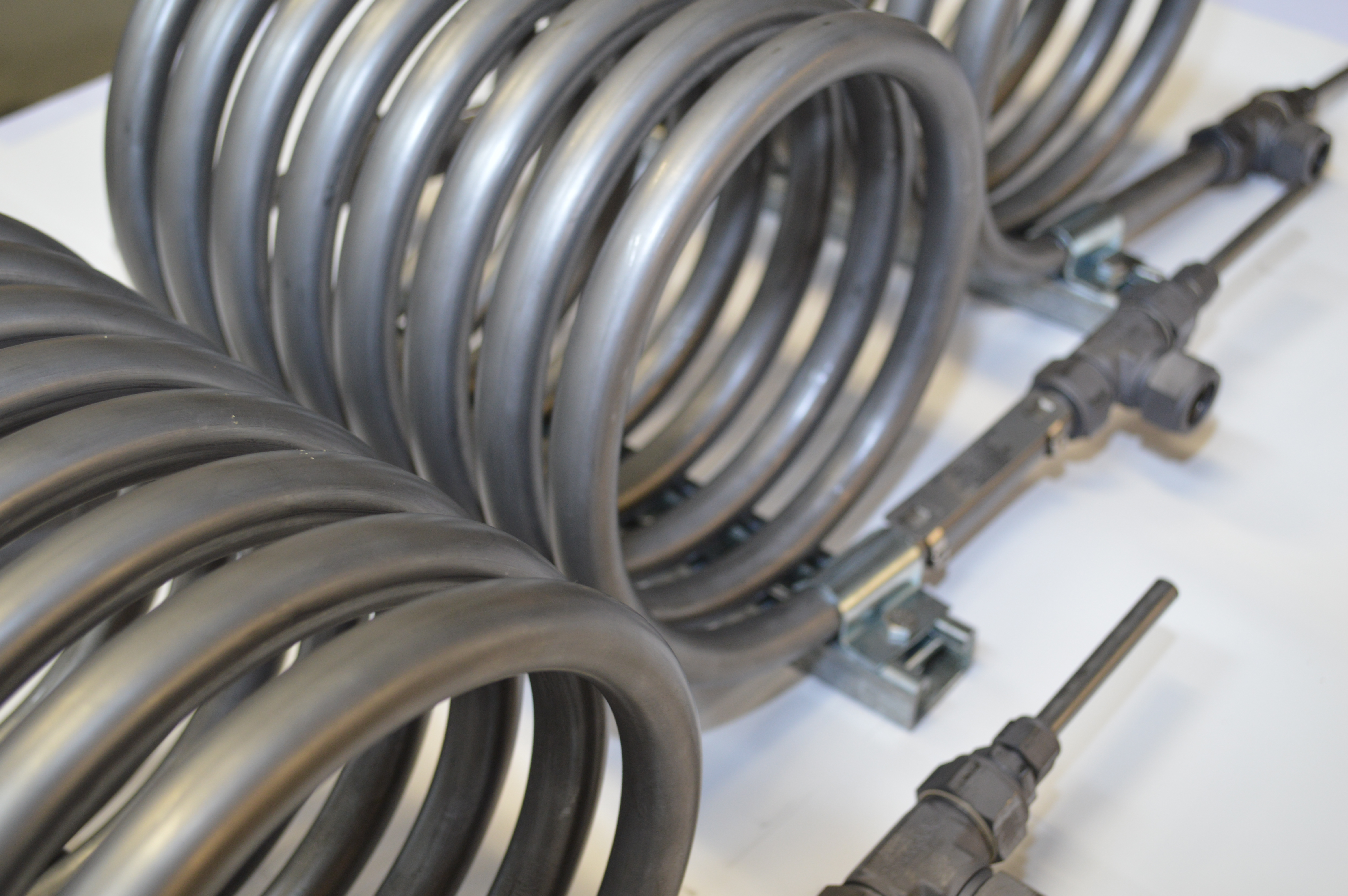

Pictured: Carbon steel tube-in-tube coils used to sample steam off of boilers.

The downside of a high concentration of impurities in the recycled water is that they can cause issues like corrosion, fouling, and scaling in the boiler. A sampling system will allow you to analyze and treat the water used in the SAGD recovery process, producing high-quality steam.

The sampling system will grab the sample of the treated water to identify its chemical characteristics and composition. This process can effectively indicate the presence of contamination and any potential fluid that may cause defects in the processing system. However, when collecting this sample it is important to consider the following factors that may affect the overall analysis:

- The pressure and temperature requirements

- Phase changes of the fluid

- The concentration of impurities which may vary at different points of the container/pipes

- Leaks or contamination in the system

A reliable sampling system will ensure true sample representativeness by making the use of specialized sampling cylinders, continuous flow systems, and sample heating/cooling systems. By analyzing the samples, the system can:

- Verify the process conditions

- Monitor water quality

- Identify the quality of the final product and its adherence to the desired specification

- Monitor environmental emissions

Leverage a Swagelok Sampling System to Reduce Production Costs From SAGD Blowdown

At Edmonton Valve & Fitting, we understand that the cost and productivity of your SAGD project are of prime importance. With our Field Advisory Services, we can perform sampling audits to identify the discrepancies in your grab and continuous sampling system and make recommendations on how to mitigate them. This is supported through grab sampling cylinders and tube-in-tube systems solutions. By understanding the processing requirement of your water samples, you can optimize the cost of your SAGD production.

To discuss the specific needs of blowdown management for your fluid system, contact Edmonton Valve & Fitting, your local fluid system expert, today. Or you can get started by downloading the Grab Sampling Systems Application Guide.

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (3)

- About Us (1)

- April 2024 (3)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)