Share this

Ensuring Efficiency for SAGD Projects in Alberta Starts Here

by Thomas Webster on Tue, Jun 08, 2021 @ 14:06 PM

With the recent rise in oil prices, numerous companies are revisiting their steam-assisted gravity drainage (SAGD) projects and maintenance plans in Alberta after the slowdown last year. The challenge facing newer engineers coming to work at SAGD sites in Alberta is where to find consistent support to maintain the efficiency and reliability of critical SAGD equipment surrounding the large number of pumps and sampling stations across a site.

Local fluid systems manufacturers bring extensive product knowledge and a wide range of application experience to help improve the efficiency of SAGD projects in Alberta. The local support from a seal flush system and sampling system designer and manufacturer can be extremely valuable when a piece of equipment is not working properly or needs to be replaced.

Let’s take a look into some of the most important equipment required for efficient SAGD operations.

Proper Equipment and Services to Ensure Efficiency for SAGD Projects in Alberta

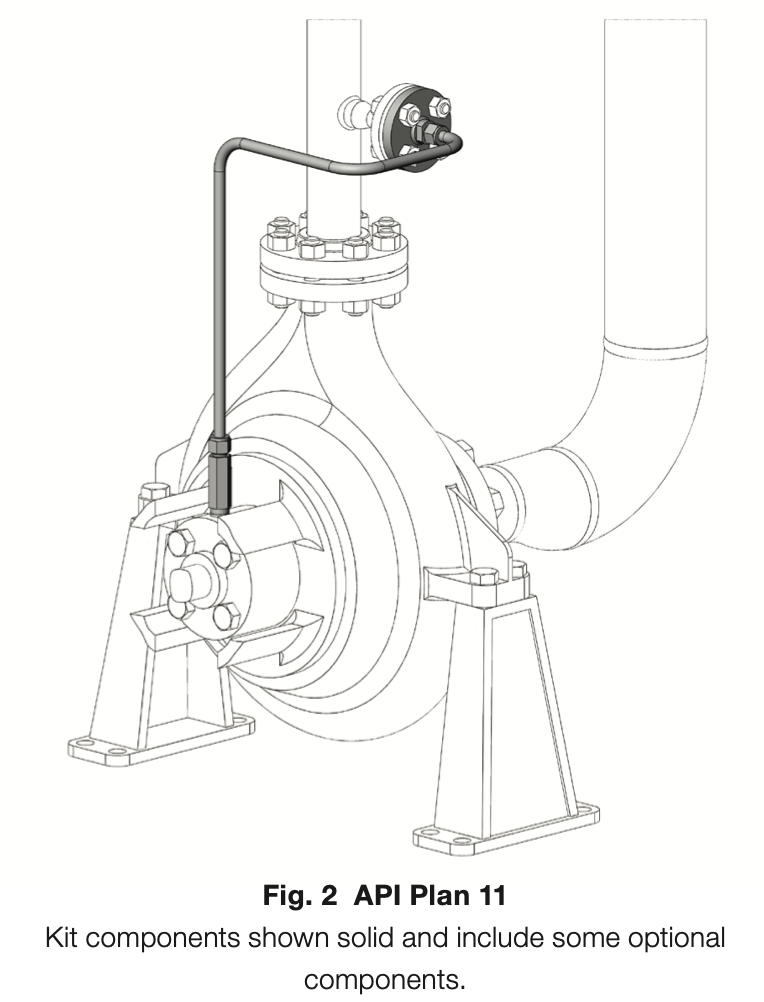

The entire SAGD process relies heavily on rotating equipment for pumping operations and sampling stations to inform processes and uphold quality control. Reliable and efficient rotating equipment operations depend strongly on seal flush systems to lubricate or flush mechanical seals of contaminants to prevent damage or failure. Sampling systems are required in SAGD to provide representative samples which may be used to validate process conditions and product quality.

Pumping Equipment

The SAGD process requires an abundance of rotating equipment including emulsion well pad pumps, boiler feed pumps, hydrocarbon transfer and treatment pumps, water treatment pumps, and export pumps. As a large source of pump failures, mechanical seals must be given special care and consideration. One of the most important factors for ensuring rotating equipment reliability and maximizing uptime is the implementation of high-quality seal flush systems. While downtime is typically unavoidable, downtime due to mechanical seal damage or failure can be greatly reduced with the right seal flush system and local support to help troubleshoot any problems that may arise.

Properly configured and implemented seal flush systems allow for streamlined operations and maintenance to ensure downtime is minimized. SAGD reliability can be greatly improved if appropriate winterization measures are taken prior to winter in cold climate operations, such as Alberta.

Properly configured and implemented seal flush systems allow for streamlined operations and maintenance to ensure downtime is minimized. SAGD reliability can be greatly improved if appropriate winterization measures are taken prior to winter in cold climate operations, such as Alberta.

As for most SAGD components and connections, considerations for material selection are critical in the prevention or slowing of corrosion that could lead to future leaks or failures. Depending on the specific application, materials such as carbon steel (ZSML), monel, inconel, and stainless steel may be implemented. Local fluid systems experts are likely to provide a more in-depth analysis of suitable material selections for SAGD applications in Alberta.

Sampling Equipment

Sampling systems are arguably one of the most critical pieces of equipment for ensuring efficiency for SAGD projects in Alberta. Sampling systems, grab or continuous, are used in SAGD to:

- Validate a number of process conditions.

- Determine water treatment efficacy to ensure reliable boiler operations.

- Monitor emission from the boiler stack.

- Verify proper separation of water and bitumen has occurred.

- Quantify the steam-oil ratio (SOR) and water-oil ratio (WOR).

- Ensure the end product meets quality specifications for internal purposes or for custody transfers.

- Validate online analyzers are “fit for use”.

The biggest challenge with sampling systems is the ability to obtain a representative sample. Representative samples are the only way to make informed decisions regarding the process and know the true quality of the product. Key design considerations, such as the reduction of dead legs and implementation of an adequate purging system, must be considered to ensure a representative sample is obtained. For grab samples, the chemical composition must be maintained when transporting the sample to a laboratory. Depending on the phase, temperature, consistency, chemical makeup, and pressure parameters, a cylinder or bottle can be used to capture the sample.

The biggest challenge with sampling systems is the ability to obtain a representative sample. Representative samples are the only way to make informed decisions regarding the process and know the true quality of the product. Key design considerations, such as the reduction of dead legs and implementation of an adequate purging system, must be considered to ensure a representative sample is obtained. For grab samples, the chemical composition must be maintained when transporting the sample to a laboratory. Depending on the phase, temperature, consistency, chemical makeup, and pressure parameters, a cylinder or bottle can be used to capture the sample.

Local fluid systems vendors can provide onsite analysis of sampling systems to provide specific recommendations on how to ensure representative samples are obtained and how to boost sampling consistency, reliability, and efficiency.

Your All-in-One Solution for Seal Flush and Sampling Systems

Access to a local fluid systems vendor can be extremely beneficial for SAGD projects in Alberta—whether that be to quickly supply tubing, fittings, or components needed throughout a project or to help troubleshoot seal flush or sampling system issues in a timely manner.

Edmonton Valve & Fitting has ample experience with seal flush systems and sampling systems for SAGD applications in Alberta and a deep understanding of the local challenges. We place focus on helping you achieve the greatest level of efficiency for all of your projects through high-quality components, seal flush systems, and sampling systems. Our Field Advisors can perform an onsite analysis of your process and equipment to ensure you are set up for project success.

If accommodating an entire team at your site is challenging, we can use our augmented reality collaboration headsets to conduct virtual evaluations to provide assistance quicker with less hassle. To learn more about how to increase efficiency for rotating equipment and energy management, check out our Mechanical Efficiency Program (MEP).

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (2)

- About Us (1)

- April 2024 (2)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)