Share this

How to Ensure SAGD Water Treatment Efficacy to Improve Plant Efficiency

by Tristian McCallion on Thu, May 06, 2021 @ 10:05 AM

Steam Assisted Gravity Drainage (SAGD) water treatment involves removing heavy metals, hydrocarbons, hydrogen sulfide, and silica, as well as lowering total dissolved solids (TDS) to produce “clean water.”

In steam production, clean water can increase boiler efficiency and prevent potential equipment failures. If the improperly treated water is sent to the boilers, there can be hard scale buildup on the inside of the boiler tubes, causing increased fuel consumption, as well as increased tube temperatures. These increased operating temperatures can result in mechanical failure within the system. Additionally, if the water is not properly treated, corrosion in the boilers can also result in mechanical failure. High operating temperatures and boiler corrosion can lead to unplanned downtime, stymying production operations.

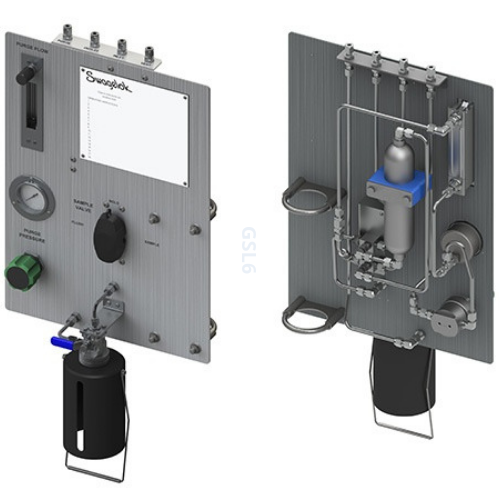

To improve production efficiency and equipment reliability, plants must leverage a grab sampling system to ensure SAGD water treatment is effective. Here, we’ll discuss the characteristics of a reliable grab sampling system and how it can increase plant efficiency.

Characteristics of a Reliable Grab Sampling System

Finding the right grab sampling system is crucial to SAGD water treatment processes. A reliable and efficient grab sampling system should:

- Provide a timely, representative sample

- Be safe and easy to use for those operating the system

- Be reliable and dependable

- Reduce plant costs

Importance of a Timely, Representative Sample

If you can’t obtain a sample that is representative of the contents of the recycled and treated water, you can’t make informed decisions that meet regulatory compliance and improve production efficiency. Without a representative sample, the efficacy of your SAGD water treatment process isn’t known, which could lead to equipment failure and unplanned downtime.

Timing is also important. The lag time between sample extraction and sample collection should be minimized to ensure a representative sample is captured. If there is too much lag time in between sample extraction and collection, the sample may not accurately reflect the composition of the pipeline.

Grab sampling provides a snapshot of the characteristics of the treated water. It may be necessary to implement a continuous sampling system to provide a more accurate and comprehensive look into the water quality.

Safety, Reliability, and Cost

It is important for a grab sampling system to provide a clear and simple sampling procedure to minimize the risk of operator error during the sampling and/or maintenance processes. Simplicity and ease of use is also a key component to safe operations. A safe system will separate process pressure from the sampling container as well as the user to prevent overpressure conditions and overfilling. This is especially important when the process liquids contain chemicals, such as hydrogen sulfide, that are highly toxic and extremely flammable.

Your grab sampling system must also be reliable in terms of functionality and accuracy. This could mean installing a custom grab sampling system configuration. The following criteria should be considered when specifying a grab sampling system:

|

Criteria |

Considerations |

|

Temperature and Pressure |

Each grab sampling system has a maximum fluid operating temperature and maximum rated pressure. |

|

Phase |

A cylindrical sampler is suitable for both liquid and vapour systems, whereas a bottle sampler is suitable for non-volatile liquid systems. |

|

Hazardous/Flammable Materials |

The system must have stringent leak and chemical protection when dealing with hazardous chemicals. |

|

Materials of Construction |

The materials and coatings used in the sampling system must be compatible with the system fluid. |

|

Surface Treatments |

A more representative sample can often be achieved by reducing the adsorption of the sample fluid via a surface treatment. |

|

Purge |

If your fluid contains a chemical that may leave residue behind, this residue must be purged from the system with a purge fluid. |

A reliable system will provide a truly representative sample and will keep equipment operating smoothly. Like any other system in the SAGD process, grab sampling systems can be a source of leaks. Thus, a system with quality tube fittings and minimal connections is critical in reducing potential leak points that could disrupt operations.

An efficient grab sampling system is one that, due to its safety and reliability by design, saves your facility time and money. In particular, this system should help you to avoid unplanned downtime and reduce water usage by streamlining the sampling process and verifying the quality of the water.

The Best Way to Ensure SAGD Water Treatment Efficacy

If you’re looking for an expert opinion on whether or not you have the right grab sampling system—or if you need to upgrade or replace your current system—Edmonton Valve & Fitting has a solution perfectly suited for you. Edmonton Valve’s Field Advisory Services can perform a grab sampling audit that will provide clear, specific recommendations on boosting grab sampling consistency, reliability, and efficiency. Our local field service technicians have deep and comprehensive knowledge regarding fluid system applications for SAGD companies.

If you’re looking for an expert opinion on whether or not you have the right grab sampling system—or if you need to upgrade or replace your current system—Edmonton Valve & Fitting has a solution perfectly suited for you. Edmonton Valve’s Field Advisory Services can perform a grab sampling audit that will provide clear, specific recommendations on boosting grab sampling consistency, reliability, and efficiency. Our local field service technicians have deep and comprehensive knowledge regarding fluid system applications for SAGD companies.

About Tristian McCallion, Custom Solutions Manager, Edmonton Valve

Edmonton Valve has relied on McCallion for 26 years. His current title is Custom Solutions Manager. Earlier, he supervised our sales team. Before that, he managed sales throughout Edmonton and northeastern Alberta. For 12 years he also worked with Swagelok Energy Advisors across North America, training customers on steam fundamentals (TAP), testing steam traps, and conducting steam system audits.

Edmonton Valve has relied on McCallion for 26 years. His current title is Custom Solutions Manager. Earlier, he supervised our sales team. Before that, he managed sales throughout Edmonton and northeastern Alberta. For 12 years he also worked with Swagelok Energy Advisors across North America, training customers on steam fundamentals (TAP), testing steam traps, and conducting steam system audits.

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (2)

- About Us (1)

- April 2024 (2)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)