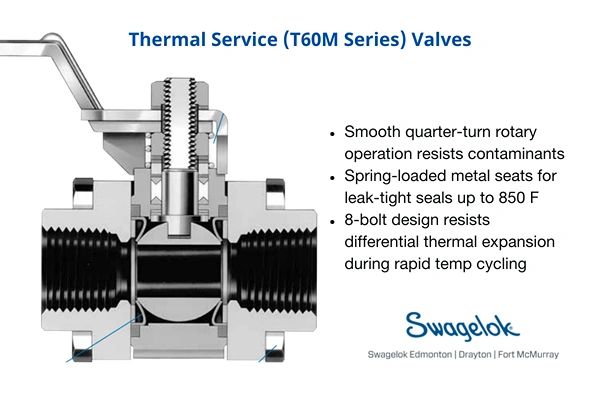

Swagelok T60M Series: Ideal Valve for Thermal Service Applications

by Derek Green on Tue, Apr 02, 2024 @ 08:04 AM

Here we'll look at the design and ideal uses of Swagelok's Thermal Service Ball Valve (T60M Series). With its innovative metal seat, this special purpose valve is designed to maintain a seal with a mi …

Choosing Swagelok Tubing & Fitting Alloys? Engineered Combinations Resist Corrosion & Minimize Cost

by Thomas Webster on Thu, Sep 28, 2023 @ 08:09 AM

Instead of using tubing and fittings of the exact same alloy material, try engineered combinations of high quality Swagelok tube fittings with more robust tubing alloys. That way you can achieve a cos …

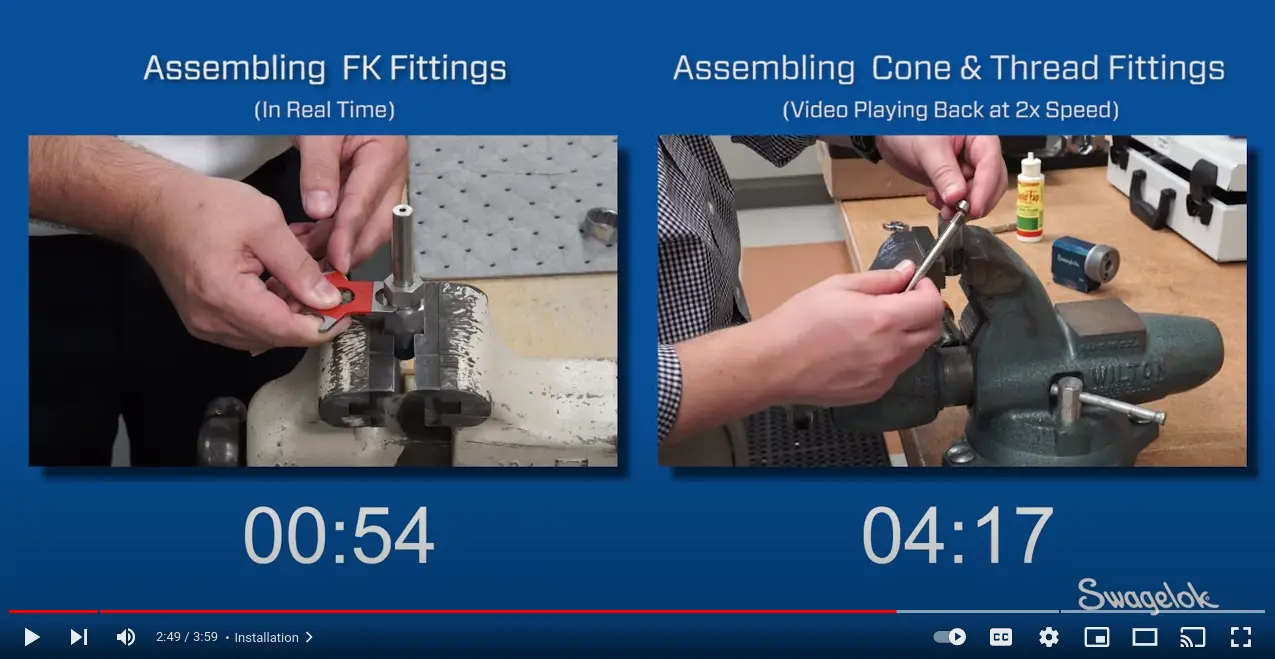

Why Traditional Cone & Thread Fitting Installation is 5x Slower Than Modern Alternative

by Katie Reid on Wed, Aug 23, 2023 @ 08:08 AM

In many critical oil and gas applications, mechanical grip medium-pressure fittings like Swagelok's FK Series offer better value than traditional cone and thread fittings. One reason is installation s …

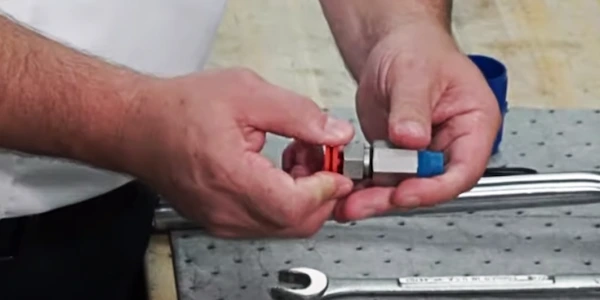

New Swagelok Training: FK Fittings Essentials

by James Dickie on Wed, Aug 02, 2023 @ 08:08 AM

What's the right way to install Swagelok's mechanical-grip FK fittings with heavy-walled tubing? Is their design all that different from cone and thread fittings? A new seminar offers answers, trainin …

SAGD Blowdown: Ensuring Your Sampling Systems Help Optimize Production Costs

by Thomas Webster on Wed, Sep 21, 2022 @ 08:09 AM

With 80% of Alberta’s oil sands buried 150 meters to 450 meters deep on average, steam-assisted gravity drainage (SAGD) is the trusted method for heavy crude oil and bitumen recovery. High-temperature …

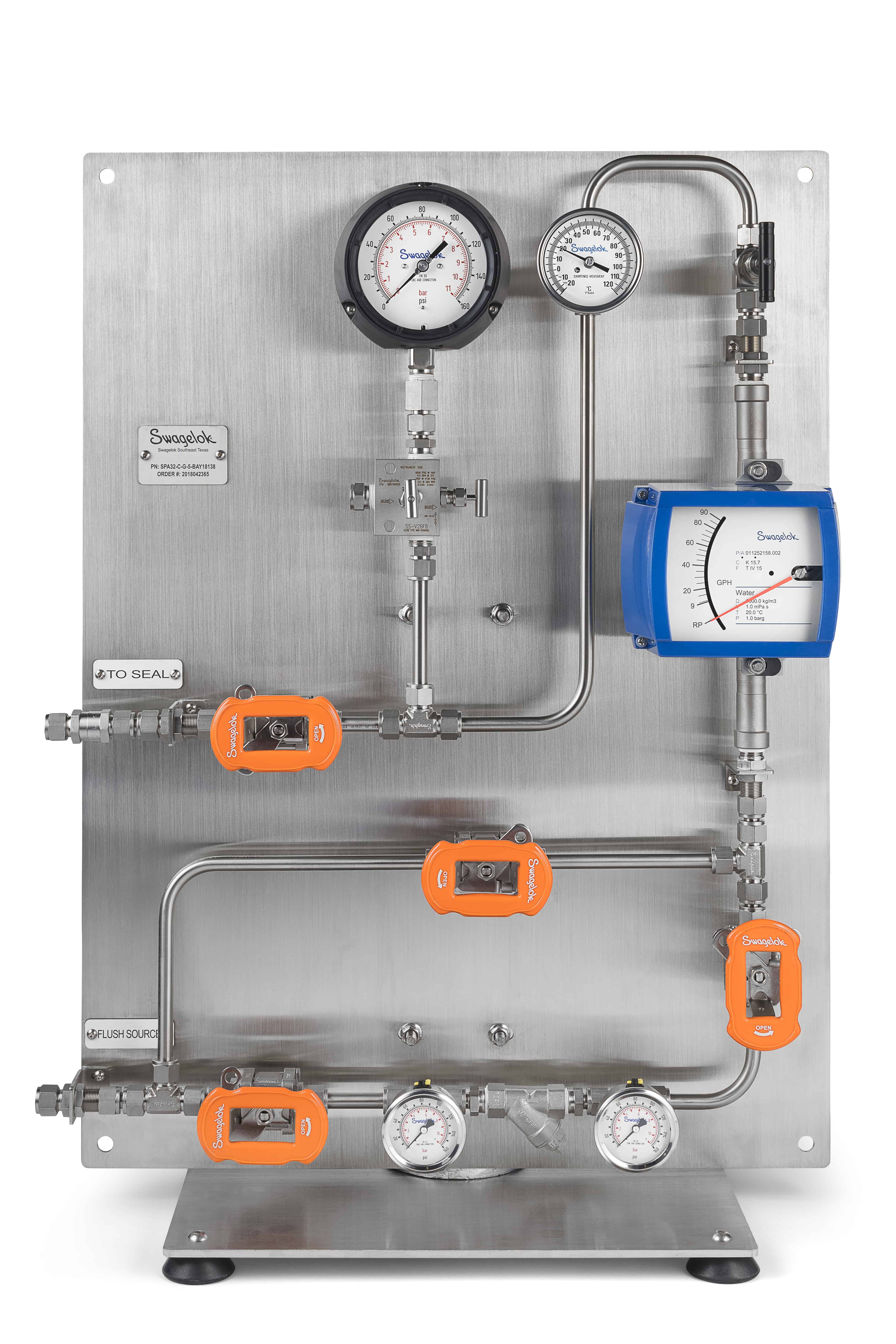

Determining a Seal Support System’s Quality Before Purchase

by Thomas Webster on Thu, Sep 15, 2022 @ 09:09 AM

What makes a high-quality seal support system? In a basic sense, we may link the quality of a seal support system to its ability to provide the ideal condition for lubrication and cooling at the seal …