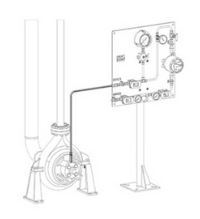

The Benefits of API Plan 32 Design/Build for SAGD Facilities or Upgraders

by Thomas Webster on Thu, Jul 22, 2021 @ 09:07 AM

Alberta SAGD operations require carefully controlled fluid pressures, so mechanical seals and seal support systems are critical to their success. The climate and high-viscosity fluids in SAGD can crea …

Why Plan 52 Failure Happens and How to Address it in Alberta Refineries

by Thomas Webster on Tue, Jul 13, 2021 @ 15:07 PM

Dual mechanical seals are often used in Alberta refineries when pumping applications involve hazardous fluids to provide an extra level of safety. To maintain proper lubrication and heat removal to du …

Solving Seal Flush Plan 11 Challenges More Easily for SAGD Operations

by Thomas Webster on Wed, Jul 07, 2021 @ 08:07 AM

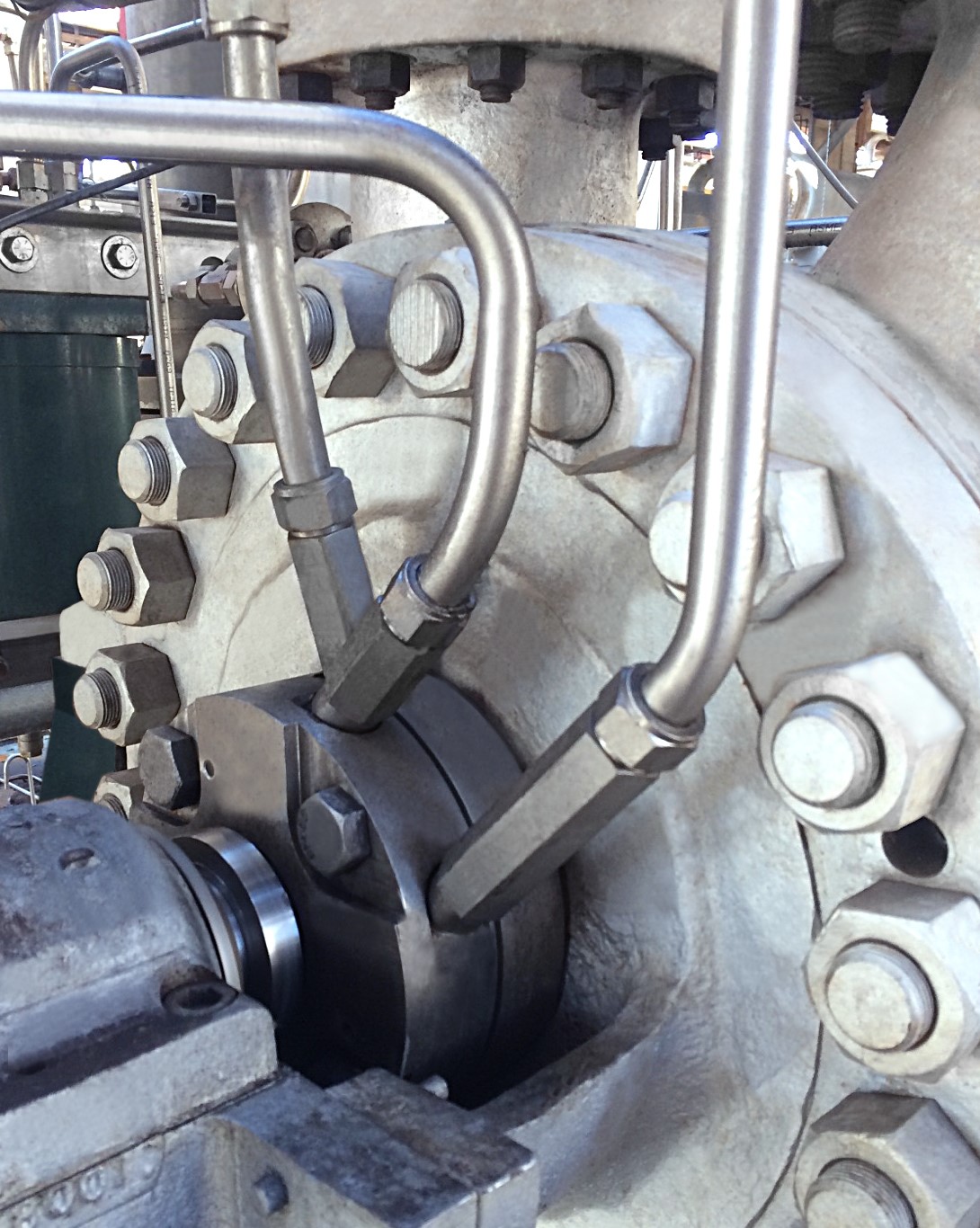

Seal flush Plan 11 is the most common piping plan used for single mechanical seals in steam-assisted gravity drainage (SAGD) operations. It is simple, inexpensive, and recirculates process fluid from …

Ensuring Efficiency for SAGD Projects in Alberta Starts Here

by Thomas Webster on Tue, Jun 08, 2021 @ 14:06 PM

With the recent rise in oil prices, numerous companies are revisiting their steam-assisted gravity drainage (SAGD) projects and maintenance plans in Alberta after the slowdown last year. The challenge …

How SAGD Challenges Can Be Met With Improved Communications

by Tristian McCallion on Thu, May 27, 2021 @ 13:05 PM

Steam-assisted gravity drainage is an enhanced oil recovery (EOR) technique that is widely used in northern Alberta to recover heavy crude oil and bitumen through steam injection. SAGD is a less invas …

How Reliability for SAGD in Alberta Can Be Improved—And Lessons for Other Remote Operations

by Thomas Webster on Thu, May 20, 2021 @ 14:05 PM

Steam-Assisted Gravity Drainage (SAGD) is an enhanced oil recovery (EOR) technology that utilizes a pair of stacked horizontal wells to recover bitumen from oil sands. Hot steam is produced in a boile …