About > Industries > Hydrogen & Clean Energy Applications

Hydrogen & Clean Energy

Learn about consulting, components, and assemblies for hydrogen applications. Browse videos, take literature. Tel: 780-437-0640.

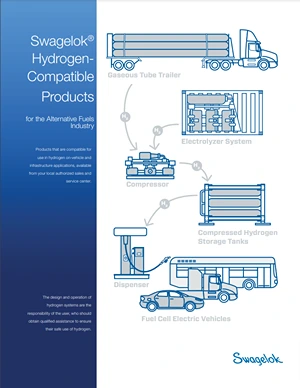

Download the Hydrogen-Compatible Products Guide

Swagelok makes components specifically engineered for hydrogen applications. This 33-page guide details hydrogen-compatible products for applications up to 1 378 bar (20 000 psig).

Hydrogen-Compatible Swagelok Products

With a suite of products for hydrogen applications, we can help you build solutions more quickly and reliably. Get product selection support online, by phone, or at one of our three branches. For online shopping click here →

Hydrogen-Compatible Tube Fittings and Weld Fittings

Standard Swagelok fittings are hydrogen-compatible. FK series fittings provide outstanding tube grip and leak resistance. We also offer assembly-by-torque (AbT) fittings and tube fittings that deliver gas-tight seals.

Hydrogen-Compatible Valves

We offer check valves for excess flow prevention in on-vehicle applications, relief valves for purge and bleed applications, and instrument manifolds that minimize potential leak points.

Hydrogen-Compatible Hose & Flexible Tubing

Our metal core hoses and flexible tubing perform well in hydrogen and CNG on-vehicle and refueling applications.

Hydrogen-Compatible Filters

Find and install all-welded inline or tee-type filters that remove system particulate contaminants from your alternative fuel systems.

Hydrogen-Compatible Regulators

Choose the right pressure regulators rated appropriately to maintain ideal pressures in alternative fueling infrastructure applications.

Hydrogen-Compatible Tubing

Our metal tubing has composition and performance required for hydrogen and CNG/LNG applications in vehicles and fueling stations.

Material difference: Only the highest grades of stainless steel can resist the introduction and diffusion of hydrogen molecules into the material. Swagelok 316 stainless steel is specifically formulated to overcome hydrogen embrittlement with enhanced strength and corrosion resistance.

Local inventory: We have listed only a few hydrogen-compatible products here. We also offer manifolds, Monel (Alloy 400) products, measurement devices, tubing supports, and orbital welding systems, for example. Get the free Swagelok Hydrogen-Compatible Components Guide for details.

Simplify selection: Get in touch for a hand choosing a product with the performance characteristics to last in your challenging application. Our staff can check stock, answer technical questions, recommend ways to save, help with product selection, expedite your order, and more.

Download Swagelok Low-E Certified Valves PDF

Learn how certified Low-E Swagelok valves help protect your people, process, and profitability—whether you are impacted by governmental regulations or looking to adopt best practices.

Fluid System Assemblies for Hydrogen Applications

We build standardized and custom combinations including gas fill panels that integrate with dispensers, compressors, and fuel lines. Projects include design support, parts, fabrication, assembly, testing, documentation, and installation support.

Grab Sample Panels for Hydrogen Applications

Swagelok grab sampling systems satisfy gas and liquid non-slurry sampling service in a reliable package.

Gas Distribution Systems for Hydrogen Applications

Our all-in-one systems deliver gasses to points of use. Configurable for application and process conditions.

Regulator Assemblies for Hydrogen Applications

Our regulator assemblies are designed for safety, easy installation, intuitive operation, and low maintenance.

Sample Cylinder Assemblies for Hydrogen Applications

Available in ten standard sizes, from 150 cm3 to 3,785 cm3. Customize with purge bypass tube.

Field Station Modules for Hydrogen Applications

Preconditions a gas sample at extraction point. Configurable and can mount to process nozzles.

Fluid Distribution Headers for Hydrogen Applications

Versatile manifold for gas and liquid applications. Can be connected for longer lengths.

Rigorous testing: We pressure test (hydro and/or pneumatic) every assembly down to 1.0 x 10-6. We also offer mass spectrometer leak detection using a Pfeiffer helium leak detector, with capability of up to 2.5 x 10-6 atm*cc/sec leak rate detection depending on the test. Both inboard and outboard testing are available.

Comprehensive support: Before fabrication, we check over your design or collaborate with you to create one. We can fabricate anything with fluid system components on it. Assemblies are ready to install and covered by the same Swagelok warranty as our individual parts. We are even onsite to answer questions at installation.

Maximum value: We use safe, reliable Swagelok components (and additional parts as needed). Our economical designs specify the fewest possible parts and connections. When lead time is short, we work to accelerate your project. Opt for final testing using gas, hydrostatic, or helium leak test equipment.

.webp)

Download Hydrogen-Compatible Assemblies PDF

Discover Swagelok custom solutions for clean energy and hydrogen applications. This pull sheet gives examples of what we can build and outlines the steps in a typical project.

Consulting & Onsite Services for the Hydrogen Industry

We advise on fluids issues in electrolyzers, micro-grids, fuel cells, virtual pipelines (tube trailers), FCEV fuel systems, dispensers and priority panels, refueling station infrastructure, and more. Opt for onsite or virtual collaboration.

Helium Testing

We offer onsite mass spectrometer leak detection with capability of up to 2.5 x 10-6 atm*cc/sec depending on the test.

Sampling System Evaluation

Receive detailed expert guidance on how to improve sampling reliability, from process tap to analyzer.

Grab Sampling Evaluation

Get clear, specific recommendations on boosting grab sampling consistency, reliability, and efficiency.

Gas Distribution System Evaluation

We check performance and components' fitness for function, including required vs. actual flow rates.

Compressed Gas Leak Detection

We detect leaks that eyes and ears miss, calculate the cost of each leak, and specify the fix for each one.

Design Advice on Fluid Systems

We can evaluate P&ID’s, CAD models, or sketches to recommend products or advance your design work.

Fluids focused: We apply fluid system expertise to help hydrogen producers, alternative energy companies, hydrogen infrastructure developers, vehicle manufacturers, and others meet the challenges of containing and transferring hydrogen. To advise you we consider plant safety, output quality, maintenance routines, and cost of ownership.

Helium testing: For mass spectrometer leak detection we use a Pfeiffer helium leak detector with capability of up to 2.5 x 10-6 atm*cc/sec leak rate detection depending on the test performed. Both inboard and outboard detection testing are available. We can helium leak test assemblies in our Edmonton shop or onsite with you.

Global network: There are dozens of certified Swagelok Field Engineers around the world, and Swagelok Edmonton's Field Advisors are part of a network connecting them all. To bring you extra value, Field Engineers/Advisors check solutions with each other and optimize according to peer review.

.webp)

Download Hydrogen Application Support PDF

Learn how we can help with electrolyzers, micro-grids, fuel cells, virtual pipelines (tube trailers), FCEV fuel systems, dispensers and priority panels, refueling infrastructure, more.

Swagelok Training for Alberta Companies

Our Swagelok-certified Trainers build skills with industry engineers, technicians, procurement specialists, and quality managers. Swagelok training is standardized so course content is the same around the world.

Custom Team Training

Bring Swagelok training to your facility or train your whole team in the Swagelok Edmonton training room.

FK Essentials

We cover design of Swagelok FK Series tube fittings, safety considerations, variables in and prep of medium-pressure tubing, and more.

Inspection Essentials

We address correct tube system placement, inspection best practices, inspection post reassembly, troubleshooting, and more.

Tube Bending Basics

In this 45 minute session, attendees gain understanding of the role of bent tubing in fluid system integrity, and more.

Tube Bending Essentials

This half-day lecture-lab dives deeper, developing a more advanced understanding of tube bending best practices.

Tube Fitting Basics

This seminar introduces personnel to best practices in proper installation of tube fittings and fittings assemblies.

Tube Fitting Essentials

This course dives deeper, developing a more advanced understanding of tube fitting installation best practices.

Total Support Training

These seminars increase attendees' skill in both tube fitting installation and proper bending and fabrication of tubing.

Hosted or onsite: Every individual and operation can improve, and the right training can quickly pay for itself. Taught at our Edmonton training facility or onsite at your facility, our seminars provide the foundational knowledge and techniques needed to build and operate high-performing fluid systems.

Safety and savings: Addressing leaking valves is probably the single quickest way to improve, research suggests. Depending on the size of your facility, there may be anywhere from 100 to over 40,000 valves installed, according to a widely referenced US EPA report. You can save by tightening up.

Inclusive training: Some Essentials seminars are designed to help installers and maintenance technicians be safe and efficient. Other Essentials seminars aim to help managers, engineers, and quality control make sure systems have been done correctly.

Reviews from Swagelok Customers

Contributors to this page:

Tom Webster

Swagelok Field Advisor, Edmonton Valve & Fitting

Tristian McCallion

Custom Solutions Manager, Edmonton Valve & Fitting

James Dickie

Training and Services Manager, Edmonton Valve & Fitting

Contact Our Clean Energy Team

Need sales, support, or information?