Download Swagelok's Small Bore Tubing Solutions Brochure (6 page PDF)

Still using pipe in small-bore applications? Why?

Compared to a piping system of comparable strength, tubing systems are substantially lighter - so easier to install and support. And that's just one of several ways that tubing may serve you better than piping in small-bore applications. Here's an example:

|

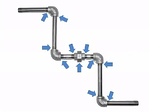

With piping

11 potential leak points Tightening of the pipe into the elbows depends on the strength of the installer. Elbows may end up being over tightened, which can damage the threads and cause leakage. Or they could be under tightened in order to line up properly and, again, result in leakage. Removal of any component requires sequential disassembly. |

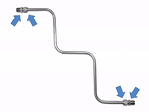

With tubing

4 potential leak points To reach from Point A to Point B, the tubing is simply bent. No extra fittings are required. A tubing bend creates less turbulence and pressure drop than a pipe elbow. Fittings are pulled up 1 1/4 turn manually or with a swaging unit to make leak-tight seals. Tube fittings allow easy access without sequential disassembly. |

(Note: Our example uses 90-degree bends, but the advantage of tubing only grows when offsets and odd angles come into play. The tube can be bent exactly as needed, saving space and improving flow.)

By itself, tubing costs more than the equivalent amount of pipe. But when you add the cost of tools and labor, then factor in how much maintenance each system needs, tubing comes out ahead.

So if you are still using pipe, why not take a look at the advantages of tubing? Fill the short form on this page for immediate access to the Small Bore Tubing Solutions catalog from Swagelok.

About Us

Founded in 1965, Edmonton Valve & Fitting Inc. provides critical fluid system components to customers throughout Northern and Central Alberta. Contact us at 780-437-0640.