Learn more about how pressure regulators are critical in maintaining proper operating conditions.

Pressure regulators help ensure systems are operating at their highest efficiency. Selecting among the types of pressure regulators presents a challenge in its own right, as the two styles operate on opposite ends of the media stream to maintain proper conditions. Beyond pressure regulator type, the mechanisms of the regulator must be taken into account for situations such as high or low-pressure work and inlet dependency. As any job calls for a precise tool, learning how to determine the best pressure regulator for an Alberta-based refinery will prioritize system efficiency.

Pressure regulators help ensure systems are operating at their highest efficiency. Selecting among the types of pressure regulators presents a challenge in its own right, as the two styles operate on opposite ends of the media stream to maintain proper conditions. Beyond pressure regulator type, the mechanisms of the regulator must be taken into account for situations such as high or low-pressure work and inlet dependency. As any job calls for a precise tool, learning how to determine the best pressure regulator for an Alberta-based refinery will prioritize system efficiency.

Pressure regulators are valves used to control fluid pressure via a negative feedback loop. The method of pressure regulation can be separated into two types: pressure-reducing regulators and back-pressure regulators. The pressure-reducing regulator samples downstream pressure and is therefore placed before sensitive equipment, while the back-pressure regulator is placed in parallel or downstream of sensitive equipment and samples upstream. To further contrast the two designs, the pressure-reducing regulator maintains a constant outlet pressure with a fluctuating supply pressure and the back-pack pressure regulator establishes a pressure maximum which causes the regulator to open when inlet pressure exceeds this value. Despite their difference in application, the two designs are quite similar: an external load applied via a spring or gas pressure pushes against one side of a piston or diaphragm operating as a sensor. On the other side of the sensing element, the fluid force of the system is measured. The difference between these two axially opposed forces guides the operation of the pressure regulator. As its name might imply, the pressure-reducing regulator reduces outlet pressure to create a constant pressure from a potential varying inlet pressure and flow rate. The fluid force of the system being equal, or slightly less than the load force allows the poppet to open, which reduces outlet pressure. The back-pressure regulator operates by keeping inlet pressure below a set level. The poppet will normally remain closed but can open when inlet pressure increases above the set pressure.

Depending on system pressure needs, a few different aspects will need to be considered to choose the best regulator:

| Pressure-Reducing | Back-Pressure |

| Samples downstream | Samples upstream |

| Controls outlet pressure regardless of inlet pressure | Keeps inlet pressure below a set level |

The action of a pressure regulator consists of three mechanisms: loading, sensing, and controlling.

The loading of the regulator can be achieved either through a load-bearing spring or a gas-fed dome chamber with a pressure slightly above that of the desired outlet pressure. For the dome-loaded regulator, a secondary regulator known as a pilot regulator supplies the necessary pressure. Additionally, differential regulators are achievable using a combination spring and dome-loaded setup. The dome load provides the reference pressure, while the spring load acts as a bias.

The style of sensing is dependent on both the loading mechanism and the pressure demands of the system. Diaphragms are encountered in all dome-loaded regulators and some low-pressure spring-loaded regulators, while a piston is used for high-pressure spring-loaded regulators due to its greater resilience to damage caused by pressure spikes.

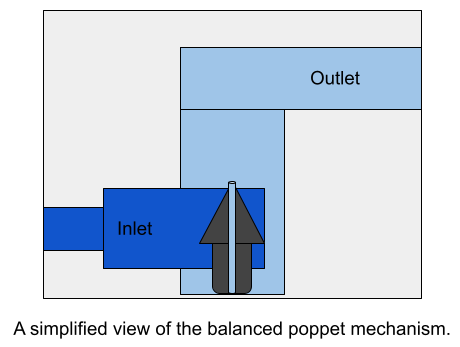

The controlling mechanism can come as one of two poppet variations: balanced or unbalanced. The unbalanced poppet has a majority of the shutoff force provided by the inlet flow pressure, whereas the unbalanced poppet features an orifice through the poppet and a balancing O-ring to reduce the area the inlet pressure acts upon. The features of the balanced poppet also contribute to a reduction in supply pressure effect (commonly abbreviated SPE), whereby an increase or decrease in inlet pressure results in a proportional decrease or increase in outlet pressure, respectively. Inlet pressure is only able to act upon the seat area of the unbalanced poppet, therefore a large change in inlet pressure allows a set spring to overwhelm the balance of forces and move the poppet away from its expected position.

In general, the larger the sensing area and the smaller the poppet, the less susceptible the regulator is to SPE. The balanced poppet features an orifice, sealed via an O-ring, which allows the outlet pressure to act upon a portion of the poppet underside. With the changing outlet pressure able to dynamically alter the area the changing inlet pressure is acting upon, the balanced poppet is able to better combat the regulator’s inlet dependency. Furthermore, the balanced poppet design counteracts the potential for lockup, which can cause downstream pressure spikes. For situations where SPE needs to be further minimized, two-stage regulators can be of use. A two-stage regulator utilizes two single-stage regulators in series: the product of the individual regulator’s SPEs serves to further mitigate the effects.

A fourth mechanical consideration for pressure regulator components is the seal style: a soft seal will provide for pressures up to approximately 1,000 PSIG and a hard seal rated up to approximately 10,000 PSIG.

Finally, some specialty regulators may be necessary beyond the standard designs. Two noteworthy features offered are vaporizing and automatic changeover regulators. A vaporizing changeover contains either steam- or electrical-heating element, with the electrical-heating element able to make direct contact with the process media. These heating elements can either vaporize liquids or heat gasses to prevent condensation. The automatic changeover regulator is a two-stage regulator system that includes a selecting regulator to switch between supplies and a linear regulator to meet requisite system pressure. When the supply pressure falls below a set level on the selecting regulator, the regulator is able to switch to an alternate supply source. Even when both sources fall below the minimum pressure level of the selecting regulator, it is able to draw both supplies simultaneously.

Sifting through the different types of pressure regulators is no simple task, but it is one that could bear enormous benefits for the efficacy of your overall system. Let an Edmonton Valve & Fitting Field Advisor audit your fluid system and offer you peace of mind, knowing that your facility uptime is being maximized to its full potential.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse tempor nisi ut vehicula commodo.

Learn More →

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse tempor nisi ut vehicula commodo.

Learn More →

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse tempor nisi ut vehicula commodo.

Learn More →

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse tempor nisi ut vehicula commodo.

Learn More →

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse tempor nisi ut vehicula commodo.

Learn More →

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse tempor nisi ut vehicula commodo.

Learn More →

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse tempor nisi ut vehicula commodo.

Learn More →

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse tempor nisi ut vehicula commodo.

Learn More →

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse tempor nisi ut vehicula commodo.

Learn More →Swagelok is a $2B developer of industrial fluid system products and services. Swagelok Edmonton is an authorized Swagelok Sales and Service Centre serving Canadian companies in clean energy, chemical, oil and gas, and other industries. Proud member of the Canadian Council for Aboriginal Business.

Tel: 780-437-0640.

Swagelok Edmonton values your privacy. This website uses cookies to enhance user experience and analyze performance and traffic. Our policies are posted here.

Login/Register | Privacy | Safe Selection | Centre Locator | Sitemap | Legal

© 2012-2024 Edmonton Valve & Fitting Inc.