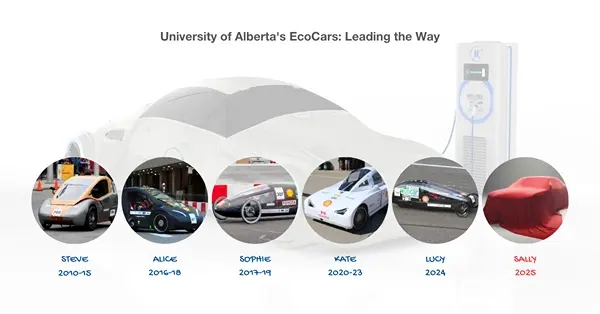

Racing Toward Sustainability: University of Alberta EcoCar Team's Journey

by Andrew Worthington on Wed, Feb 12, 2025 @ 14:02 PM

The Shell Eco-Marathon challenges student teams worldwide to design, build, and drive vehicles that push the limits of fuel efficiency. Among these passionate innovators is the University of Alberta's …

Consistent & Repeatable Coiled Tubing Designs Fabricated In-house with Less Lead-time

by Ryan Meissner on Thu, Nov 21, 2024 @ 16:11 PM

Whether you need long, continuous tubing for use in drilling and well operations or tubing coils fabricated for heat exchange, seal pots, or other process systems, we are now better equipped than ever …

Unlocking Regulator Performance: How to Read Flow Curves (with Bulletin, Training, More)

by James Dickie on Thu, Oct 24, 2024 @ 12:10 PM

I'll try here to give a short, clear explanation of what a flow curve is, why it matters, and how to interpret it. I'll touch on common issues like droop and choked flow, providing practical examples …

Master Regulator Selection & Troubleshooting: New Swagelok Training

by James Dickie on Mon, Oct 07, 2024 @ 14:10 PM

How do I select the right type and size regulator? What should I look for in regulator performance? Is droop avoidable? Our new Regulator Selection and Troubleshooting Training (RSTT) provides answers …

Master Small-Bore Tubing Systems: New Swagelok Training

by James Dickie on Thu, Aug 08, 2024 @ 06:08 AM

With small bore tubing systems at chem and refining facilities, what is the best way to install tube fittings, then inspect and maintain them? What about selecting tubing, preparing it, bending it, in …

From Our Shop to You: New Guide Highlights Our Fabrication Capabilities

by Tristian McCallion on Tue, Jul 02, 2024 @ 07:07 AM

We have a new Fabrication and Assembly Services PDF available for download. It shows the specialized services we developed in response to demand from our customers for tailored fabrication solutions. …