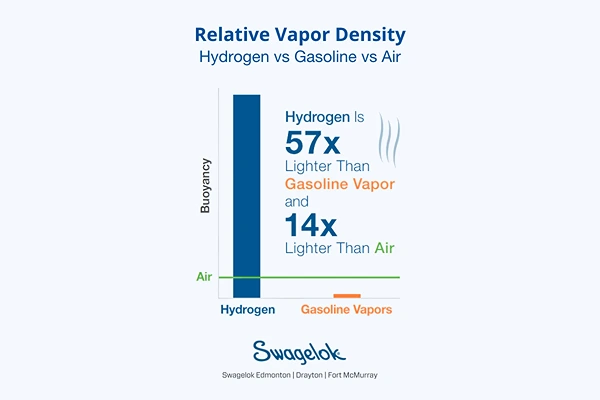

Myth: Hydrogen Gas Leaks are More Hazardous Than Gasoline Leaks

by Derek Green on Wed, Apr 24, 2024 @ 06:04 AM

Hydrogen, being nontoxic and less volatile, can pose fewer hazards than conventional fuels. In this article we look at relative vapor density, oxygen concentrations, and autoignition temps; offer a ne …

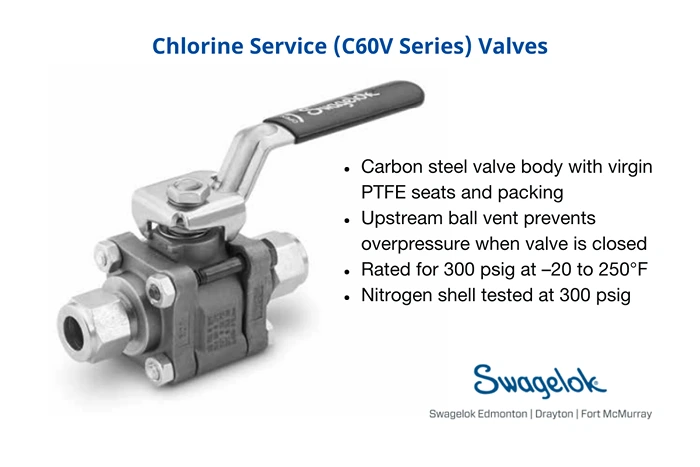

Swagelok Valve for Chlorine Service: Ball Vent and Carbon Steel Body

by James Dickie on Tue, Apr 09, 2024 @ 07:04 AM

Swagelok's C60V Series valves, designed for chlorine applications, combine carbon steel bodies with virgin PTFE seats for optimal safety and adherence to Chlorine Institute guidelines. These valves fe …

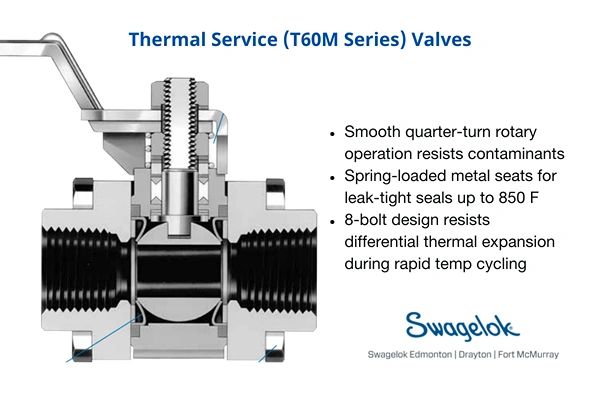

Swagelok T60M Series: Ideal Valve for Thermal Service Applications

by Derek Green on Tue, Apr 02, 2024 @ 08:04 AM

Here we'll look at the design and ideal uses of Swagelok's Thermal Service Ball Valve (T60M Series). With its innovative metal seat, this special purpose valve is designed to maintain a seal with a mi …

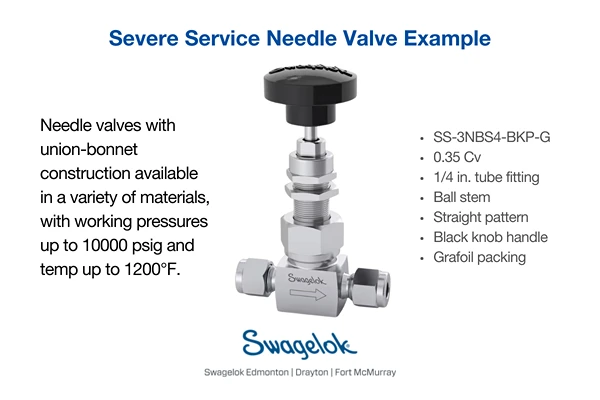

Choosing the Right Swagelok Needle Valve: Guidelines and 3 Examples

by Tristian McCallion on Tue, Mar 26, 2024 @ 08:03 AM

Today we focus on selecting needle valves, taking into consideration general and severe service valves along with the various stem tips available. A new video from Swagelok shows the design difference …

Keep Analysis Accurate and Consistent with Regular Cylinder Inspections

by Adam Telenko on Thu, Mar 21, 2024 @ 10:03 AM

Our customers need to evaluate cylinder assemblies regularly to spot any damage or wear. Swagelok Edmonton's Cylinder Maintenance Program provides this essential service. Learn what we check and downl …

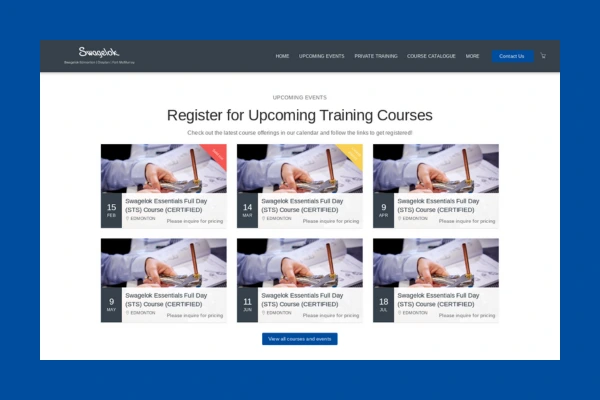

Swagelok Edmonton Training Portal: 20+ Class Options, Course Details, & Secure Registration

by James Dickie on Wed, Jan 31, 2024 @ 08:01 AM

Swagelok Edmonton has created a new online portal where Alberta fluid system engineers, technicians, and quality control managers can explore our training options, dig into course details, and registe …