Products > Regulators

Swagelok Regulators

Download Swagelok® catalogues and local PDFs, explore options, and compare features. Check FAQs and tips videos. Tel: 780-437-0640.

Download Swagelok Regulators Catalogues

In one email receive catalogues for RHPS, K, HF Series plus a technical bulletin.

Control Pressure with Swagelok Regulators & Assemblies

Scroll below to see some of the regulators we offer. To choose among them, first consider functionality, then inlet pressure, then outlet pressure. Finally, consider sizing, materials of construction, and how it connects into the larger system. Want a hand? Please use the "request details" button.

Our local team offers quick quotes, product selection advice, and daily shipping. If we can help in any way, please message us or call 780-437-0640.

Swagelok Regulator Design and Manufacturing

Swagelok regulators' reliability is the product of advanced product design, the industry's strictest manufacturing process controls, and performance verification through rigorous testing protocols. Benefits include:

Reliability

Breadth

Certifications

Materials

Manufacturing

PTRs

Expertise

Speed

Warranty

Examples

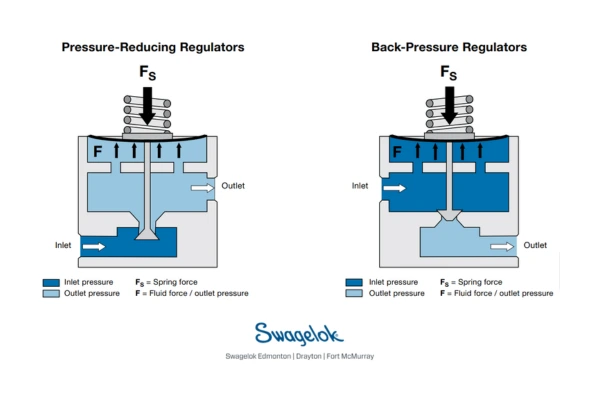

How Swagelok Regulators Work

A pressure regulator uses a piston or diaphragm as a sensing element. This element faces a spring-induced load force (FS) on one side and the system fluid's force (F) on the other. In a pressure-reducing regulator, it maintains near-constant pressure despite varying inlet pressure and flow by balancing the fluid force (F) with or slightly below the load force (FS), opening the poppet. A back-pressure regulator prevents inlet pressure from exceeding a set level, opening or closing the poppet based on whether fluid force (F) matches or falls slightly below the load force (FS), to manage pressure variations.

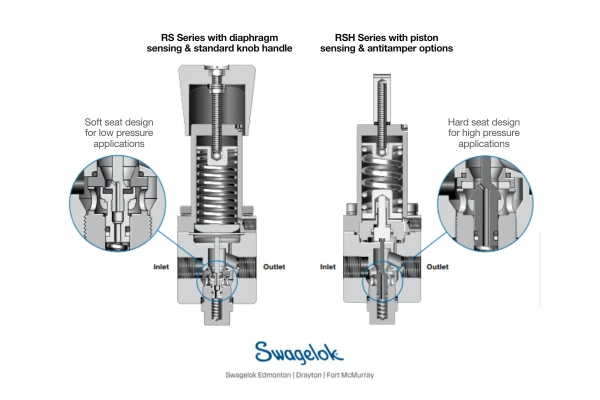

RS and RSH Regulator Design

Swagelok's RS series regulators offer poppet designs, diaphragm or piston sensing, and various materials for different conditions, with spring-loaded control and options for adjustment. Constructed from 316L stainless steel for corrosion resistance, they handle pressures from 232 to 10,150 psig. The RSH series caters to high pressures, while the LRS and LPRS focus on low pressure, high accuracy. Options include gauge connections, self-venting, filters, feedback, antitamper features, special cleaning (ASTM G93 Level C), and compliance with NACE MR0175/ISO 15156.

K Series Regulator Design

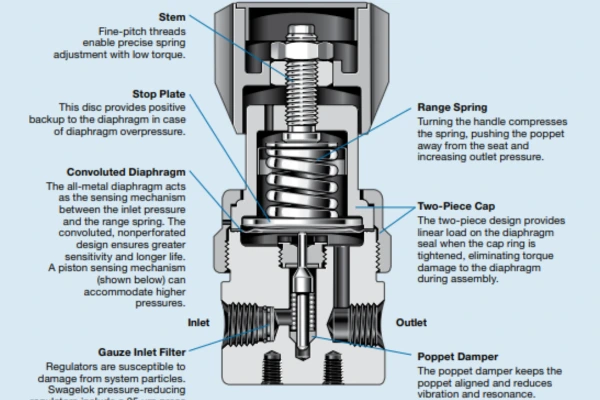

Swagelok's K series regulators feature fine-pitch threads for precise, low-torque spring adjustment and an all-metal diaphragm for sensitive pressure balance. Their convoluted design enhances sensitivity and durability, while a piston option supports higher pressures. Adjusting the handle controls pressure by moving the poppet. The two-piece cap design ensures even diaphragm pressure, preventing damage during assembly. Additionally, a poppet damper aligns and stabilizes the poppet, minimizing vibration. To protect against system debris, these regulators come with a removable 25 µm filter.

Download Gas Distribution Best Practices Collection

Receive an application guide, technical briefing video, brochure, case study, and more.

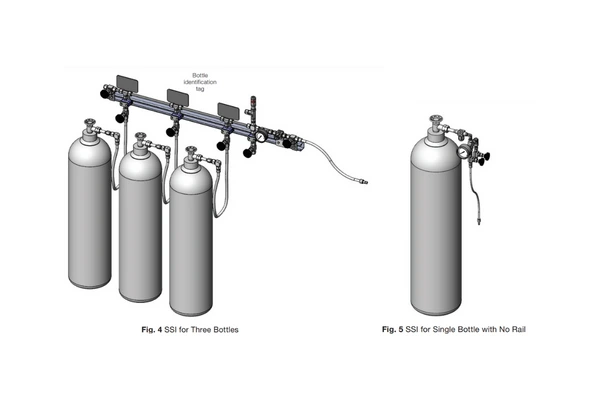

Swagelok Gas Distribution Program

Problems with gas distribution can mean losing gas, low quality product, slow downs, and hazards. We offer a solution that combines pressure control advisors and fully assembled gas distribution systems.

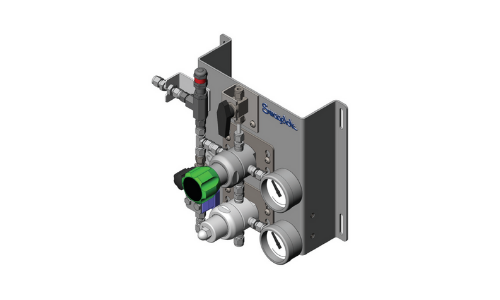

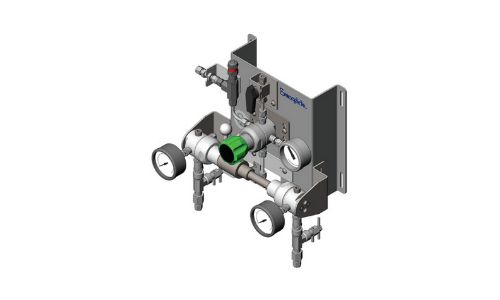

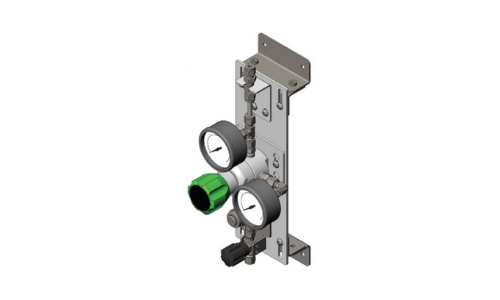

We offer analysis to inform regulator selection, identify system upgrades, and produce solutions. We can inspect, consult, advise, then deliver a fully engineered system built with minimal threaded connections to avoid leaks, clearly labeled for safety and functionality, that is easy to operate and service. Your system is assembled and tested before it leaves our shop, and backed by Swagelok's strong warranty. See the next section for literature on this option.

Saving with Fully Built, Leak-Tight Assemblies

We design, fabricate, and test fluid system assemblies for customers, right here in Edmonton.

We combine safe, reliable Swagelok components to produce assemblies for gas distribution, grab sampling, mechanical seal support, and other uses. We also build hose, bend tubing, and make filter retainer assemblies, for example. Design support, fabrication, assembly, and pressure testing are included! We can be onsite at installation too.

Videos

Swagelok Assemblies Enhance Charbonneau Production

Charbonneau Industries uses custom fluid system assemblies from Swagelok to speed up its production process, reduce labor costs, and enhance the quality of its engineered products for the oil and gas industry.

CEPSA Chooses Swagelok for Safety and Flexibility

For global energy company CEPSA, safety and the availability of a range of reliable products is paramount. Learn how Swagelok fulfills those needs while also providing training and other support.

Swagelok Edmonton Helps Customers with Regulators

It's crucial to spot regulator issues like creep before they pose safety risks or demand excessive resources. Swagelok Edmonton's pressure control experts can provide assistance and support.

Regulator Types

There are pressure-reducing regulators and back-pressure regulators. Explore options and their applications with Swagelok's product managers and field engineers.

Regulator Function

Regulator Performance

Frequently Asked Regulator Questions

Two main types: K Series and RHPS Series.

Swagelok's K Series regulators are common in analytical instrumentation applications. Swagelok RHPS Series regulators are an excellent starting point for general gas pressure regulator needs. RHPS regulators feature a soft or hard seal for pressure demands up to 1,015 psig and 10,150 psig, respectively.

Pressure-reducing regulators reduce a high pressure to a low pressure. This is usually what people have in mind when they think of pressure regulators. Back-pressure regulators control an upstream pressure. These regulators are very often used when a minimum upstream needs to be maintained through a system or where very fine overpressure control is needed. A video above on this page covers key concepts.

We are here to answer questions and help with regulator selection. Please use a green button to get in touch on this page or call 780-437-0640.

At Swagelok Edmonton we typically ask some combination of five basic questions:

What type of regulator are you going to be using? Usually it will be a pressure-reducing regulator or a back-pressure regulator.

What is the inlet and outlet pressure ranges? Generally speaking, you'll want a regulator designed to operate across a range beyond the pressures you are using. For instance, if the desired outlet pressure is 500 psi, you wouldn't want the control range operating 0 – 500 psig. You would want it rated at twice that. The middle is where you get the most accurate reading.

Will you be running a gas or a liquid through it? Gasses can be compressed, but liquids can't. That makes liquids a little easier to deal with.

What is the operating temperature?

What is the flow requirement?

We are here to answer questions and help with regulator selection. Please get in touch through this web page or call 780-437-0640.

Below are three options. Above on this page is a video that outlines what to expect.

Customer Support: Our friendly experts are happy to help you find exactly the right configuration, sized properly for your application. Just click a green "Request Details" button on this page to get the ball rolling.

Urgent Technical Support: Have an urgent technical issue? Get help diagnosing & resolving fluid system issues with our 24x7 Field Advisory Services On-Call Technical Support at 780-237-7109.

Custom Assemblies: You can opt to get a fully built, leak tight assembly that exactly fits your system. Design support, fabrication, assembly, testing, documentation, and installation support are included.

We are here to answer questions and help with regulator selection. Please get in touch through this web page or call 780-437-0640.

Do not mix or interchange product components with those of other manufacturers. Doing so voids the warranty.

We are here to answer questions and help with regulator selection. Please get in touch through this web page or call 780-437-0640.

Yes, our Field Advisors do that. Here are tips.

A regulator not operating as expected can affect the entire system, making it critical to determine the issue quickly. We recommend talking our Swagelok Field Advisors -- our elite problem solvers. Just click a green button on this page to get the ball rolling.

Keep in mind that every regulator is susceptible to creep. That's an increase in outlet pressure that occurs when pressure escapes, even though the poppet is closed.

The root cause of the problem is in the seat itself. Regulator seats can be compromised by particulates in the process stream, which can cause minor imperfections in the sealing surface. The high flow and small orifice that is created in a pressure regulator combine to turn a very small particle into a fast projectile. This projectile can nick the sealing surface of the seat and cause leakage. Any other damage to the poppet or the seat can also cause creep. Using a regulator with a soft seat can reduce the opportunity for creep.

One good way to prevent creep is with upstream filtration. Make sure you are removing all particulates from the process stream before it reaches the regulator. Some regulators include an integral filter upstream of the seat to help protect the seat. This small filter can reduce the potential for creep and increase the life expectancy and accuracy of your regulator.

To learn more, please download the literature offered at the top of this web page. Need sales, support, or information? We are ready to help. Please click "Request Details" on this page.

Here's a A droop definition & tips on minimizing.

An increase in flow causes a decrease in outlet pressure in the case of pressure reducing regulators. This is called droop. It is primarily caused by the set spring. The more flow required, the more the set spring relaxes and loses load force, causing the outlet pressure to drop.

Droop can be prevented in several ways. By using a longer spring or by using a dome loaded regulator, the effect of droop can be minimized. You can also use a regulator with external feedback or with a pilot regulator, as they have flatter flow curves than a spring loaded regulator.

Be sure to download all the resources on this page, so that you get a copy of our Flow Curve Technical Bulletin and other guidance.

We are here to help identify the correct regulator, including configuration, materials of construction, and optional features for a particular application. Just click "Request Details" to get the ball rolling.

For personalized, up-to-the-minute answers to sales and support questions, please use green buttons on this page to request details/quote.

If you prefer to find answers yourself, visit products.swagelok.com, register for an account, and start exploring. Anyone can register, and completing the entire registration form will allow you to view pricing, order online, request quotes, store favorite products, assign customized part numbers, and save or forward your shopping cart. Register or log in →

For 24x7 technical support call 780-237-7109. Request the on-call Field Advisor to discuss your technical question.

For 24x7 parts call 780-437-0640. Select "Emergency Service". Request to buy outside regular hours.

Our local team offers quick quotes, product selection advice, and daily shipping. If we can help in any way, please message us or call 780-437-0640.