Share this

Modifying a Mechanical Seal Support Assembly Drawing to Fit Your Alberta Facility

by Thomas Webster on Thu, Oct 06, 2022 @ 09:10 AM

Installing a safe and reliable mechanical seal support system is not an easy feat. The mechanical seal support system regulates the fluid system environment to set process conditions, ensuring process temperature adjustment and leakage control. For system efficiency, each plan needs to be carefully configured with high-quality components to prevent malfunction.

API plans are designed to improve the quality of operation of the seal support system. By customizing these plans, your mechanical seal support system can meet the unique safety requirements required for your operation. To get the best performance out of your system, it’s recommended that you reach out to a local fluid system expert for guidance on design support and to modify your mechanical seal support assembly drawing to fit your specific needs.

Possible Modifications To Your Seal Support System Design

Along the process side, in-between, or on the atmospheric side, your seal support assembly will have a unique seal support plan. This will include a flush plan, buffer/barrier fluid plan, quench, and leakage collection plan. When carefully considered, these plans facilitate the efficient performance of your rotating equipment.

Flush Plans

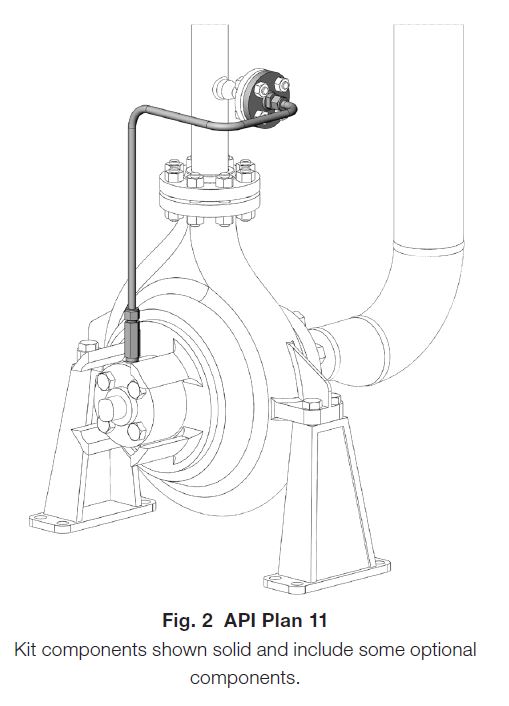

The flush plans are usually applicable for single mechanical seals. A basic plan will cover the strategic placement of flow equipment to support the recirculation of process fluid from the pump system to the seal chamber. Various arrangements of the mechanical seal support assembly can be established under this plan using the following versions of the API flush plan:

The flush plans are usually applicable for single mechanical seals. A basic plan will cover the strategic placement of flow equipment to support the recirculation of process fluid from the pump system to the seal chamber. Various arrangements of the mechanical seal support assembly can be established under this plan using the following versions of the API flush plan:

- Plan 11– Flush

- Plan 12– Flush with strainers

- Plan 13– Flush from chamber to suction

- Plan 14– Combination of Plan 11 and 13

- Plan 21– Cooled flush

- Plan 23– Cooled flush circulated through seal chamber

- Plan 31– Flush with cyclone separator

- Plan 32– External flush

- Plan 41– Cooled flush with cyclone separator

These plans allow modification with the addition of strainers, or cyclone separators to reroute the flow of process fluid to the seal chamber with internal or external porting options.

Buffer/ Barrier Fluid Plan

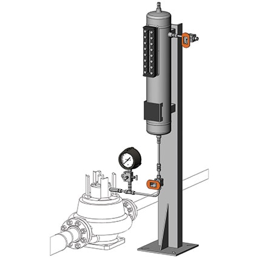

The buffer/barrier fluid plan focuses on the secondary mechanical seal and emphasizes the use of pressurized/unpressurized fluid to reduce the chance of seal damage and process fluid leakage into the atmosphere. The variations of this plan include the following API versions:

- Plan 52– Buffer fluid seal pot

- Plan 53A– Barrier fluid seal pot pressurized by nitrogen

- Plan 53B– Barrier fluid pressurized by bladder accumulator

- Plan 53C– Barrier fluid pressurized by piston accumulator

- Plan 54– Barrier fluid pressurized by external system

- Plan 55– Buffer fluid circulated by external system

- Plan 72– Buffer gas

- Plan 74– Barrier gas

Additional Plans

In addition to these established plans, in the case where the dual mechanical seal isn’t applicable on the atmospheric side, a dead-end quench system can be established. Typically used with vertical pumps, the quench system prevents ice formation around the seal when working with cold fluid. API Plan 51 and Plan 62 provide variation when the quench system has to be adopted.

Customize Your Mechanical Seal Support Assembly Drawing With the Help of Local Experts

Making a design decision about your mechanical seal support is heavily dependent on the process conditions and environment at your facility. Through careful selection of your mechanical seal support plan, you can leverage the full potential of the pumping system at your Alberta facility.

At Edmonton Valve & Fitting, we provide Field Advisory Services to evaluate your specific fluid system needs. Our experts can perform a thorough evaluation of your mechanical seal support system and support the modification of your mechanical seal support assembly drawing whenever required. Along with the customization of the flushing and piping plans, we also offer guidance in the selection and assembly of the right components. With the right recommendations on seal support assembly plans and component selection, the mechanical seal support system at your facility is sure to be safe and efficient.

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (3)

- About Us (1)

- April 2024 (3)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)