Share this

Solving Seal Flush Plan 11 Challenges More Easily for SAGD Operations

by Thomas Webster on Wed, Jul 07, 2021 @ 08:07 AM

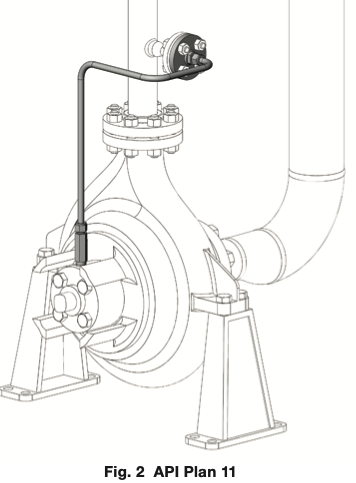

Seal flush Plan 11 is the most common piping plan used for single mechanical seals in steam-assisted gravity drainage (SAGD) operations. It is simple, inexpensive, and recirculates process fluid from the pump discharge to the seal. In SAGD applications, seal flush Plan 11 may be used for single mechanical seals on pumps ranging from emulsion well pad pumps to export and sales pumps.

Due to the high viscosity of the process fluid (crude oil)—and the use of process fluid to flush the process side of single mechanical seals—challenges with circulation and flow are common in SAGD. Crude oil is highly viscous and is more likely to contain particulates that may clog the seal itself or the flow control orifice, resulting in insufficient flow to the seal chamber. Leakage in seal flush Plan 11 piping can also cause pumping inefficiencies and is typically the result of too many leak points in the design.

Let’s take a deeper look into:

- How seal flush Plan 11 works

- Common challenges associated with SAGD operations

- Potential solutions

Seal Flush Plan 11: An Overview

API Plan 11 is the default flush plan for single mechanical seals and is categorized as a process side plan. This plan utilizes process fluid, recirculating flow from the discharge piping (or another high-pressure section) of the pump through a flow control orifice and to the seal. Seal flush Plan 11 features include:

- Heat removal from the seal chamber

- Prevention of process fluid vapourization

- Self-venting seal chamber (on horizontal pumps)

Considerations for API Plan 11:

- Careful calculation is required to determine orifice size.

- Process fluid containing abrasive solids or polymerizing process fluid should be avoided.

- Proper orifice sizing and throat bushing clearance are required for appropriate flow to the seal.

Seal Flush Plan 11: Common Challenges in SAGD Operations

Two of the most common challenges with seal flush Plan 11 are:

- Plugged seal or orifice

- Leakage in piping connections

Plugged Seal or Orifice

Due to the high viscosity of crude oil involved in SAGD pumping applications, one of the most common issues associated with Plan 11 is plugged seals or orifices. This often results in insufficient flushing and cooling of the seal and can ultimately cause downtime due to mechanical seal damage or failure. Orifice clogging can be confirmed by checking pipe or tube surface temperatures upstream and downstream of the orifice.

Leakage in Piping Connections

When excessive amounts of piping connections are used to route flow from the pump discharge piping to the control orifice and to the seal, leakage is very common. This can result in compromised piping integrity and/or inefficient flow to the seal.

Potential Solutions to Common Challenges

There are a few methods to address issues relating to plugged seals or flow control orifices and leakage. Below, we have detailed potential solutions for each problem.

Addressing Plugged Seals or Orifices

When seals and orifices plug, they can typically be cleaned out. However, when plugged seals or orifices are an ongoing problem, it might be time to reassess process conditions. As the composition of process fluid and water content changes over time, the ability of the fluid to flush and cool the seal can weaken. Recalculating the circulation flow rate, heat removal, and orifice size may show that a different orifice size may be required.

If process conditions do not require a change in orifice size and the seal or orifice continues to clog, it might be necessary to upgrade the seal flush plan. If the cause of clogging is due to solids and particulate matter in the process fluid, a simple upgrade to API Plan 12 is a potential solution. This plan is similar to Plan 11 but utilizes a strainer that is placed prior to the flow control orifice to remove such particulates. This plan also includes pressure gauges on either side of the strainer to monitor for servicing.

If Plan 12 is still insufficient in solving plugging-related issues, a more robust plan that utilizes either a buffer or barrier fluid (as opposed to the process fluid itself) can greatly reduce clogging issues. API Plan 52 is a great starting point when looking to upgrade.

Addressing Leakage in Piping Connections

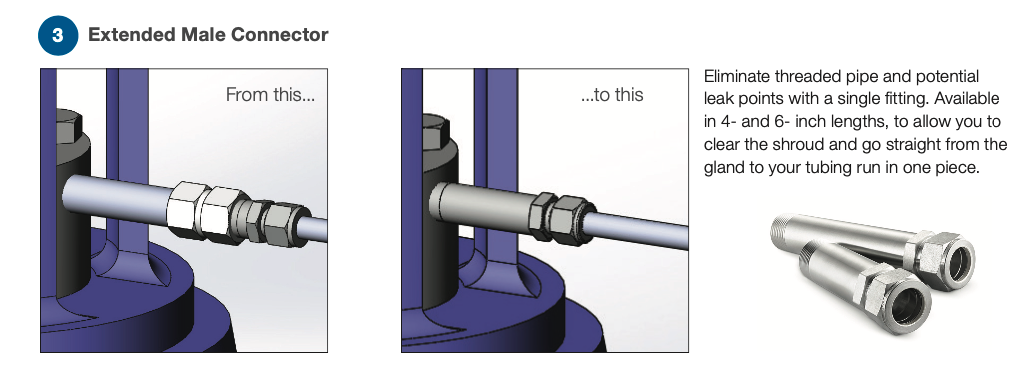

A simple solution to leakage in piping connections is to make use of fitting kits and specialty fittings that aim to reduce leak points. Every connection should be viewed as a possible leak point. Specialty connectors, such as the extended male connector shown below, can replace threaded pipe connectors, eliminating the leak point altogether.

The Best Solution to Seal Flush Plan 11 Challenges

Edmonton Valve & Fitting has ample experience with seal flush systems for SAGD applications in Alberta and understands the local challenges associated with heavy crude oil. Whether you need help addressing seal flush Plan 11 challenges—or you are looking to upgrade to a more robust solution—our Field Advisors can perform a fluid systems evaluation to determine the best solution to improve seal flush performance and reliability for your SAGD operations. We also offer fitting kits and specialty fittings and connections to reduce leak points and minimize rotating equipment downtime.

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)