Share this

Why Plan 52 Failure Happens and How to Address it in Alberta Refineries

by Thomas Webster on Tue, Jul 13, 2021 @ 15:07 PM

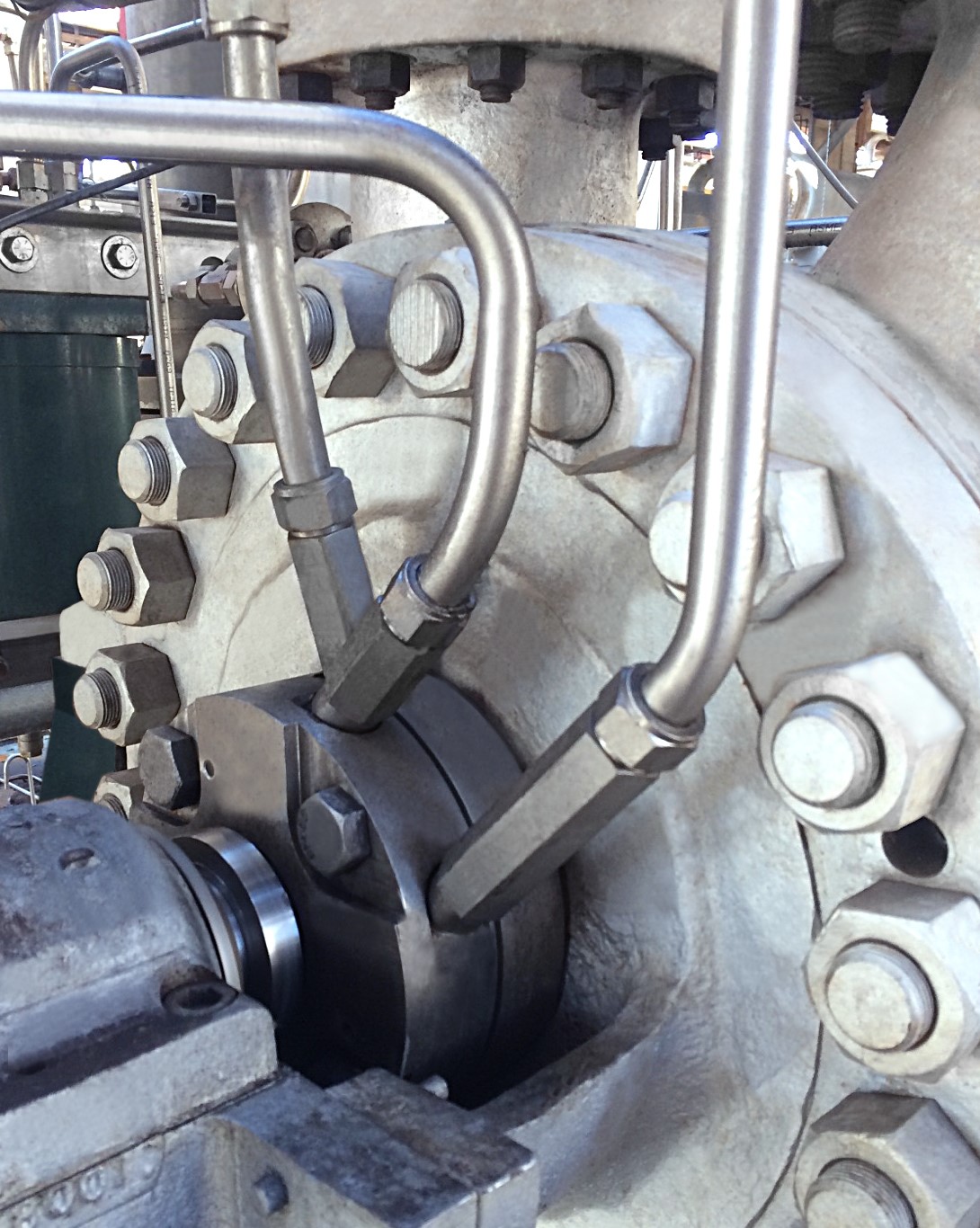

Dual mechanical seals are often used in Alberta refineries when pumping applications involve hazardous fluids to provide an extra level of safety. To maintain proper lubrication and heat removal to dual mechanical seals, a seal flush system is required. Unpressurized configurations require the use of a buffer fluid, whereas pressurized configurations use barrier fluids.

API Plan 52 is the most commonly used seal flush system for unpressurized dual mechanical seals and circulates buffer fluid between inboard and outboard seals. If preventative measures are not taken, API plan 52 failures can occur and result in downtime. Let’s take a look at how the plan works for dual mechanical seals, common API Plan 52 failure modes, and how to prevent such failures.

API Plan 52: An Overview

API Plan 52 is often used for refinery applications involving light hydrocarbons or fluids with high vapour pressure, but may also be used for lower vapour pressure process fluids. This plan delivers and circulates an unpressurized buffer fluid between inboard and outboard seals from an external reservoir (seal pot). The reservoir typically contains an internal cooling coil or external water or air cooler to remove heat. An internal pumping ring, located between the inner and outer seals of the dual seal configuration, provides positive circulation through the flush system and into the seal chamber while the pump is running. API plan 52 provides lubrication, flushing, and cooling to the outboard seal and cooling to the inboard seal.

The advantages of API Plan 52 include:

- Lack of process contamination

- No direct leakage of process fluid to the atmosphere

- Not required to maintain pressure system, as seen in Plan 53A

Common API Plan 52 Failure Modes

When a dual mechanical seal leaks or fails with an API Plan 52 seal flush system, the most common causes of failure are heat checking, coking, corrosion, and blistering on seal faces. Below we have detailed common causes of seal failure for dual seals utilizing Plan 52, the associated symptoms, potential root causes, and solutions.

|

Failure Mode |

Symptom |

Potential Root Causes and Solutions |

|

Heat Checking |

Heat checking is characterized by radial cracks originating from the center of metallic, tungsten carbide, or ceramic seal faces. Heat checking is typically caused by insufficient lubrication, inadequate cooling, or a combination of both. |

Potential solution: If heat checking is severe, the mechanical seal may need to be replaced or upgraded to a more resilient material. If heat checking is minor, take measures to ensure the seal flush system is providing the proper lubrication and cooling to seal faces. |

|

Coking |

Coking appears as a black build-up or abrasive sludge on the atmospheric side of the seal face and can compromise the mechanical seal performance due to the impeded buffer fluid flow. |

Potential solution: When coking is discovered, use steam to remove debris and sludge from the atmospheric side of the seal. For a more permanent solution, API Plan 62 can be utilized, as it is designed to prevent coking on seal faces. |

|

Corrosion |

Corrosion occurs as the result of metal atoms being oxidized by a fluid, resulting in loss of material on the surface of the seal face. Corrosion and pitting are often the results of a chemical attack on the seal face material. |

Potential solution: If corrosion develops, assess chemical makeup of process fluid to determine the correct material for seal components and faces. |

|

Blistering |

Blistering can occur as the result of a thermal attack and is characterized by raised circular sections on carbon seal faces. Misalignment of faces due to blistering can cause seal leakage. |

Potential solution: If blistering is minor, take measures to ensure proper cooling and circulation of the seal face. If blistering is severe, consider upgrading the seal to non-porous material. |

Proactive Measures to Reduce API Plan 52 Failures

While addressing heat checking, coking, corrosion, and blistering in Alberta refineries may often mean replacing parts depending on the severity, there are a number of proactive measures that can be taken to reduce the likelihood of failure of dual seals with an API Plan 52 flush system. Here is a quick checklist of preventative measures to improve cooling and lubrication efficacy and efficiency:

- Assess process conditions to determine if the appropriate buffer fluid is being used to prevent heat checking.

- Check and replace buffer fluid on a regular basis to ensure contaminated fluid is not causing coking.

- Check pumping ring functionality to prevent insufficient circulation of buffer fluid.

- For highly viscous fluids, such as heavy crude oil, ensure that a buffer fluid is selected that will not readily mix with process fluid and reduce cooling properties.

- As process conditions change, determine whether or not the buffer fluid and process fluid are still compatible.

- Assess cooling coils on a regular basis and descale if necessary.

- Implement additional instrumentation and evaluate functionality of existing instrumentation, such as a pressure switch in the seal pot that allows for early detection of high pressure. Note that the buffer fluid should be maintained at a pressure less than the seal chamber and less than 40 psi. An increase in seal pot pressure can be a sign of inboard seal leakage.

- Avoid running pumps when the seal pot level is low, as indicated by a level gauge.

- Verify the seal pot vents remain open at all times.

Still have questions on how to improve API Plan 52 cooling and lubrication efficiency? Field Advisors at Edmonton Valve & Fitting can perform an onsite or remote inspection of your process and seal flush system to determine the cause of inefficiencies. We can make recommendations on upgrades, component materials, tubing diameters, and instrumentation to help deter API Plan 52 failures.

Share this

- Fittings (82)

- Cost Savings (70)

- Valves (67)

- Fabrication (59)

- Services (41)

- Videos (33)

- Steam Systems (29)

- Training (27)

- Downloads (25)

- Resources (25)

- Sampling (24)

- Tubing (24)

- Field Advisors (18)

- Hoses (12)

- Oil & Gas (10)

- Regulators (9)

- Winterization (9)

- Gas Distribution (7)

- Hydrogen & Clean Energy (4)

- About Us (2)

- Measurement (2)

- February 2025 (1)

- November 2024 (1)

- October 2024 (2)

- August 2024 (1)

- July 2024 (1)

- June 2024 (4)

- April 2024 (4)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)