Share this

New Technical Briefing: Grab Sampling Best Practices with Mike Strobel

by Katie Reid on Wed, Mar 03, 2021 @ 15:03 PM

Learn about a recent presentation on grab sampling best practices by Swagelok's Mike Strobel, BSc., IE, Field Engineer/Americas.

Recently Edmonton Valve customers attended a briefing by Swagelok's Mike Strobel that focused on best practices around grab sampling.

Recently Edmonton Valve customers attended a briefing by Swagelok's Mike Strobel that focused on best practices around grab sampling.

Grab sampling is the science of safely capturing a sample from a process, pipeline, or tank while maintaining the chemical composition during storage or transport for later analysis. Worker safety and ensuring samples are representative and timely are grab sampling's main goals. Other common names for grab sampling are "laboratory sampling", "field sampling", and "spot sampling".

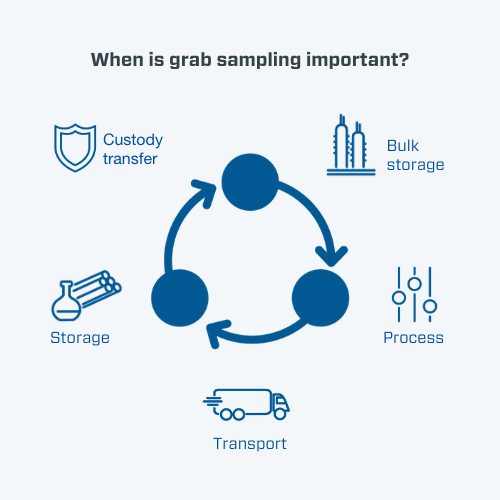

Grab sampling is particularly important for:

- Validation of process conditions

- Validation of the spec of end products

- Validation of online analyzers

- Loading platforms, reference sample of sold product

- Registration of environmental emissions according to local regulations

There are three key design considerations, having to do with continuous flow, "flush" time, and purge fluid. With respect to cylinder sampling, specifically, Strobel says best practices call for operators to:

- Fill in vertical orientation

- Fill liquid from the bottom of the cylinder (this ensures a full cylinder; ensure you use an outage tube, which creates vapor space to avoid over pressurization)

- Fill gas from the top of the cylinder (so any liquid droplets shoot straight through and any liquid on the walls is pushed out the bottom or drained by gravity)

With respect to bottle sampling, best practices call for operators to:

- Use needles and septum (make sure to consider viscosity of the fluid and particle size when sizing needles)

- Use shroud to guide bottle into needles (this reduces the risk of bending needles)

- Use a fixed volume sampler if overfilling is a concern

- Never flow or dump onto the ground

Replay this recorded technical briefing here:

Configurable. Local. Reliable.

Configurable. Local. Reliable.

Swagelok grab sampling systems satisfy gas and liquid non-slurry sampling service in a consistent, reliable package. Two system types allow for capture into one of two types of containers: pressure‑containing metal cylinders as found in the Grab Sample Module (GSM) or non-pressure‑containing glass or polyethylene bottles as found in the Liquid Only Sampling Module (GSL).

Visit the section of our website devoted to showing you the innovative grab sampling solutions Swagelok has brought to market:

Also see:

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (3)

- About Us (1)

- April 2024 (3)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)